Standards

DIN 53512, ISO 4662, ASTM D 1054, ASTM D 7121, DIN 13014 (Foam)

Measurement method

Pendulum rebound resilience measurement (Schob type)

Test modes

Single, Median of 3 tests (with 3 conditioning hits)

Operation

Fully automated with automatic pendulum lift and release

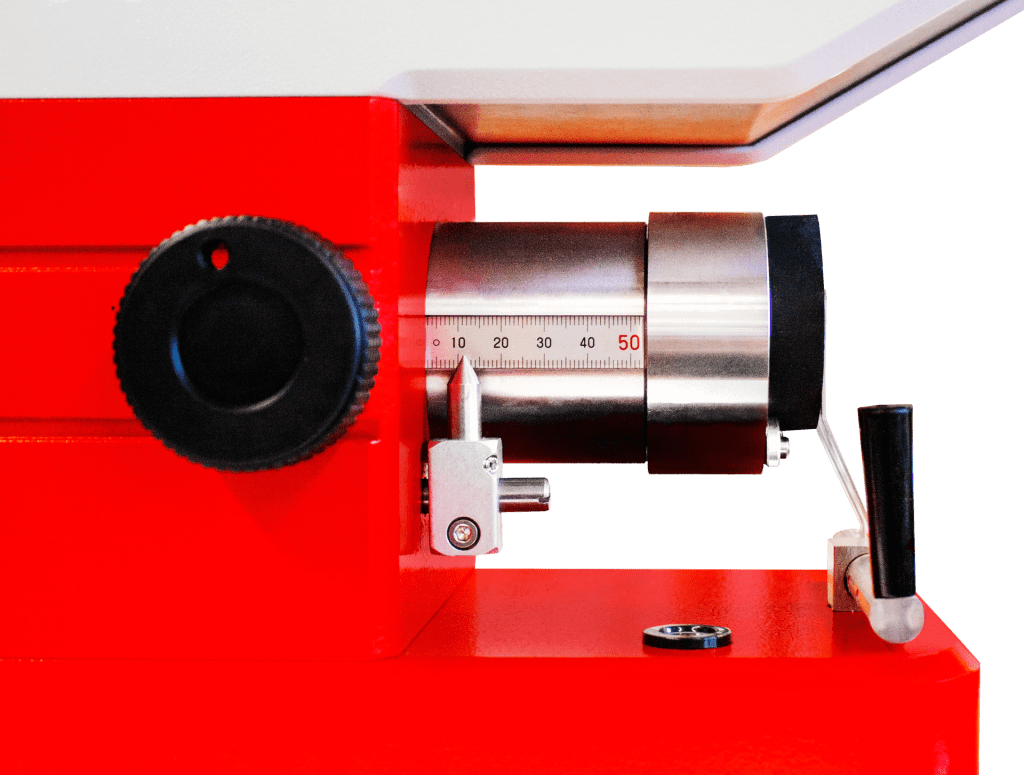

Sample dimensions

Cured rubber buttons or sheets with 0 to 20mm thickness 28 to 65mm in diameter or 50 x 50mm in size