Mooney Viscosimeter

Mooney Viscometers are the backbone for testing the viscous flow of raw materials such as polymers and intermediates such as masterbatches for maintaining stable and consistent manufacturing processes.

Moving Die Rheometers are the standard testing method for characterisation of rubber curing in quality control as well as research and development.

Mooney Viscometers are the backbone for testing the viscous flow of raw materials such as polymers and intermediates such as masterbatches for maintaining stable and consistent manufacturing processes.

The laboratory bale cutters provides the most convenient solution to cut and slice polymers bales, blocks and rubber sheets.

Carbon black dispersion tester – Computer aided, advanced digital reflected light microscopy brought to the next level.

Test instrument for measurements of the density of rubber mixtures.

State of the art fatigue testing and lifecycle simulation instrument.

Test instrument for measurements of the shore hardness and the density of rubber mixtures.

MonTech offers a wide range of sample cutters equipment for every need.

The most advanced and fully automated testing solution for high capacity mixers

Automatic Schob pendulum impact elasticity tester for elastomers and foams

The MonTech Rapid Plastimeter measures the plasticity, flow and viscosity of polymers and unvulcanized rubbers. The instrument is typically used in conjunction with the MonTech Ageing oven AO 3000 for plasticity testing to determine the Plasticity Retention Index (PRI) of raw natural rubbers.

Compression set fixtures enable measurements of a rubber compound’s ability to return to its original thickness after prolonged compressive stresses.

MonTech offers a wide range of sample cutters and specimen preparation equipment for every need.

The MonTech VP 3000 and LP 3000 are specifically designed for rubber applications and have evolved into the international standard in laboratory presses in the rubber industry.

Product

Brochures

Mooney Viscometers are the backbone for testing the viscous flow of raw materials such as polymers and intermediates such as masterbatches for maintaining stable and consistent manufacturing processes.

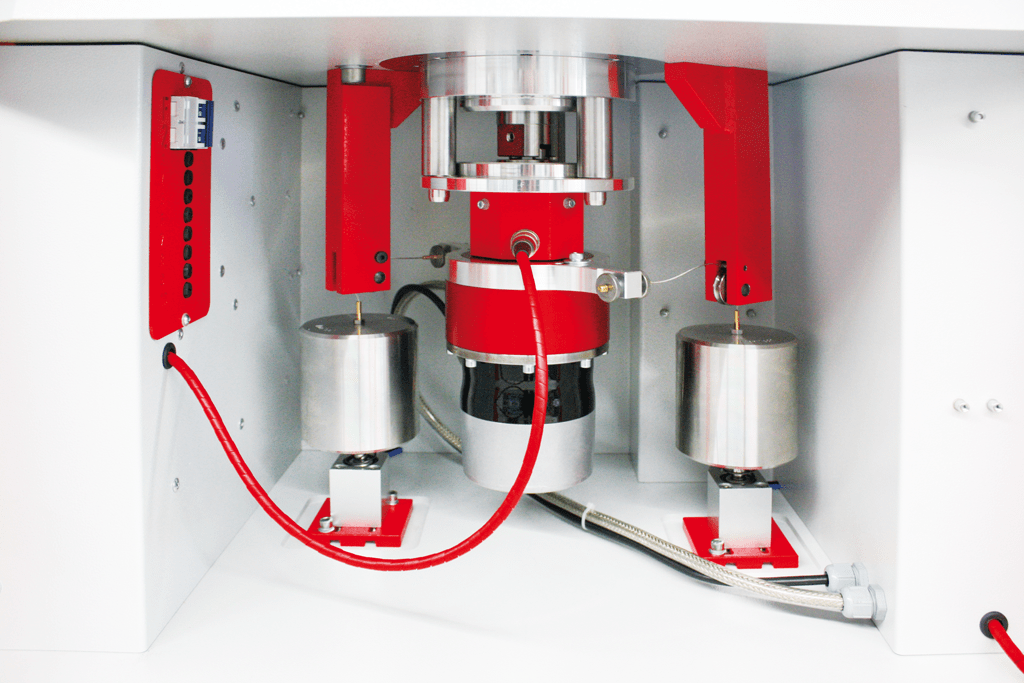

A rotational shear viscometer according to Mooney for performing Viscosity tests (ML / MS 1+X), Stress Relaxation testing, Mooney Scorch, Delta Mooney testing on polymers as well as rubber compounds for quality control, research and development applications.

DetailsStandard instrument for QC and R&D testing according to international standards.

DetailsHigh-end instrument for QC as well as dynamic R&D testing with maximum flexibility featuring variable rotor speed and temperature sweeps as well as block programming with multi-step stress relaxation.

DetailsAll MonTech Mooney Viscometers also allow Scorch as well as Stress Relaxation testing.

Mooney Viscometers are the backbone for testing the viscous flow of raw materials such as polymers and intermediates such as master-batches for maintaining stable and consistent manufacturing processes.

Furthermore, all MonTech Mooney Viscometers also allow Scorch, precise Stress Relaxation as well as Delta Mooney testing in accordance with latest international standards.

PDF DownloadContact us today for a demonstration using your compounds and materials!

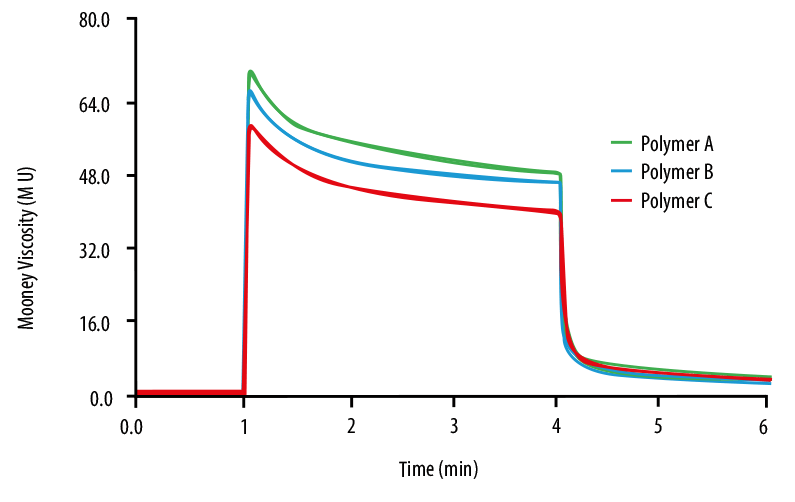

The Mooney Viscosity test is the most popular test method for characterizing polymers and uncured rubber materials. As defined by international standards, the sample material is preheated for a defined period in a closed die cavity, then sheared by the embedded rotor at a constant rate. The Mooney Viscosity is recorded and data is automatically calculated at predefined time and viscosity points. MonTech Mooney Viscometers offer superior precision and repeatability, providing the user with reliable data and making it easy to differentiate between different types and grades of polymers in order to ensure a high processing consistency.

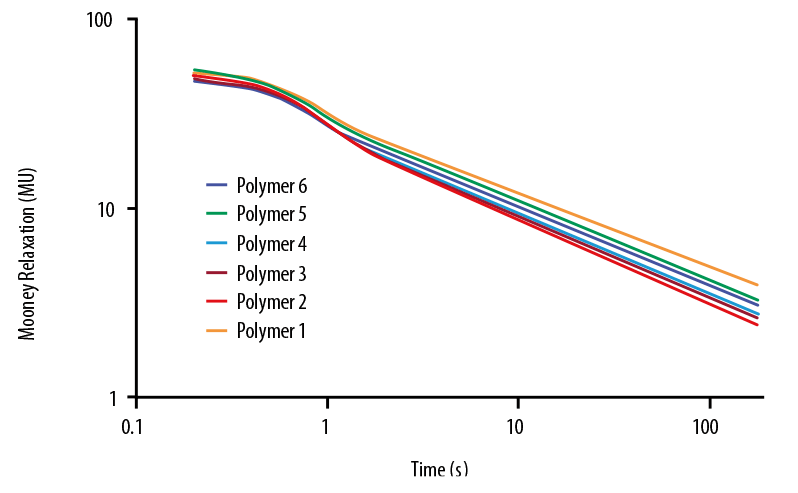

As Mooney Viscosity testing only provides information about the flow = viscosity of polymers and rubber compounds, stress relaxation testing can be used to assess elastic material behavior. This does not even require additional samples or testing efforts. Once the Mooney Viscosity test is completed, the rotor is stopped within 5 milliseconds and the torque decay is observed and recorded. Once the stress relaxation is completed, the slope-intercept and regression coefficient are calculated, providing excellent correlations in reference to polymer branching and processing.

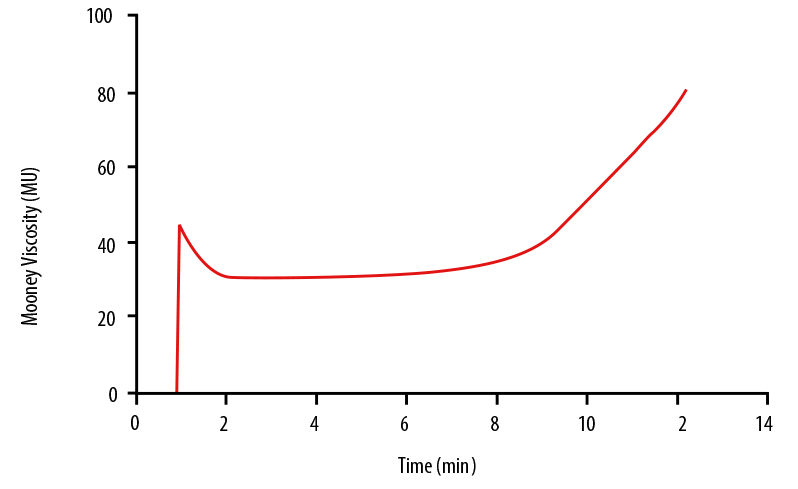

Mooney Scorch is one of the most useful tests to determine starting of cure - so called scorching behavior - of rubber compounds, providing essential data for designing and controlling production processes as well as checking material consistency. Of course, every MonTech Mooney Viscometer offers full Mooney Scorch and Delta Mooney testing capabilities featuring a selection of over 3500 datapoints which include initial Mooney viscosity, minimum viscosity, scorch times and scorch viscosities.

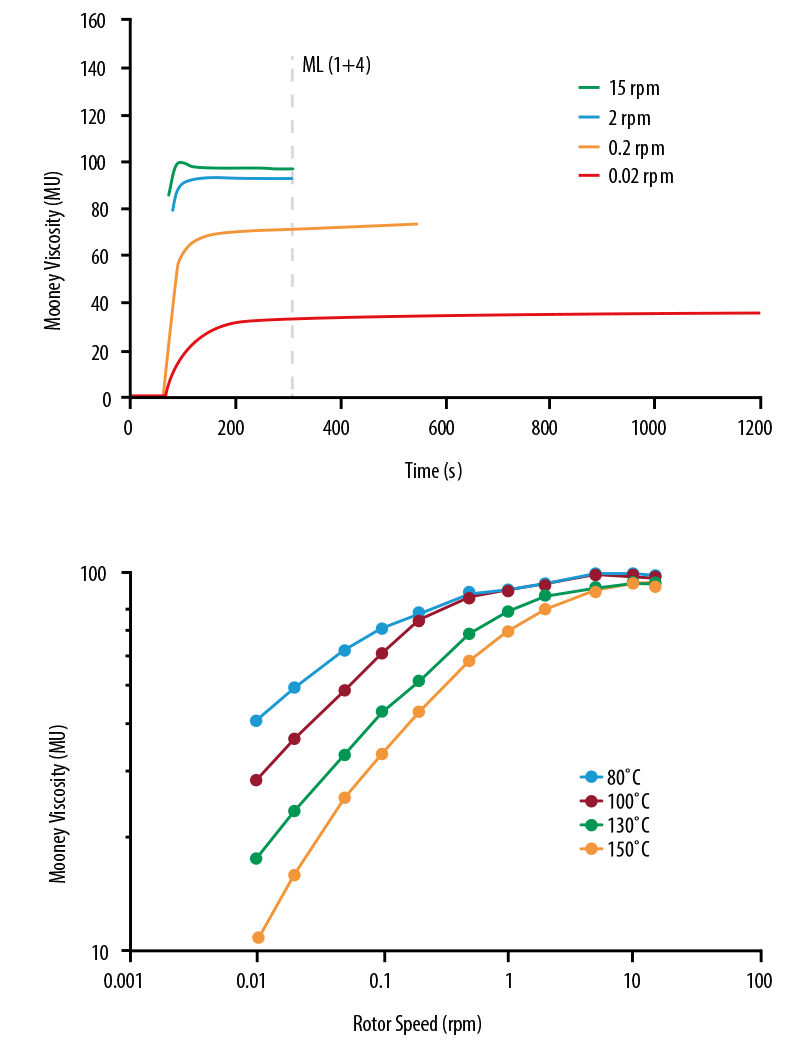

Besides only static testing, MonTech Variable Mooney Viscometers such as the V-MV 3000 offer full dynamic testing capabilities, allowing measurement of viscosity at variable shear rates (by stepless changes of the rotor speed) and temperatures. Furthermore, even non-isothermal sequences, variable rotor speed profiles as well as step-relaxations can easily be programmed and executed. Overall, this allows a detailed and complete understanding of the polymer behavior. Along with this, low rotor speed rates in Mooney Viscosity testing even provide the ability

to test highly elastic and shear sensitive materials that could not be properly tested and characterized on Mooney Viscometers before.

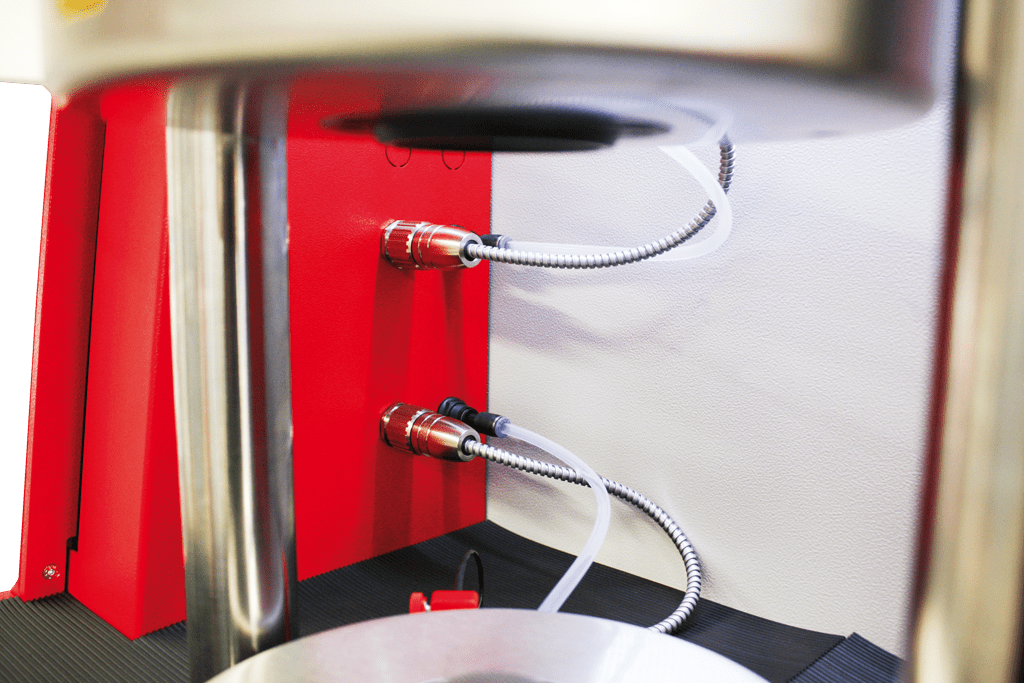

Both test dies are cooled separately by a PID-controlled forced air cooling system.

This system can be used to rapidly cool the Viscometer from a higher testing temperature (e.g. testing Mooney Scorch at 160°C) to a lower testing temperature (e.g. Mooney Viscosity testing at 100°C), significantly reducing operator waiting and nonproductive times of the instrument.

On the V-MV 3000, this option can further be used for running Non-Isothermal testing sequences as well as actively cooling friction heat.

Integrated cartridge cooling system that allows cooling of the test dies and rotor below room temperature down to +10°C, adding additional test capabilities especially for low viscosity materials such as silicones, latex and epoxy resins. This technology is worldwide patented by MonTech.

From harsh mixing plants to cleanrooms, special environments demand special encapsulation and protection of the computer system for controlling and managing the instrument. MonTech therefore offers machine integrated and machinemounted computer systems in various protection ratings, guaranteeing the highest reliability under even toughest environmental conditions.

The 5“ Color-Touchscreen allows the machine to be operated from a remote computer or completely standalone for simple quality control testing.

Compatibility to older host or software systems as well as interfacing with proprietary third party software systems are no problem for MonTech testing instruments. Every machine can be equipped with a serial RS-232 bidirectional interface to program the instrument as well as retrieve test data and results by a simple, standardized ASCII protocol.

All test results can be directly printed from the instrument through an optional printer. Of course, reports for single test results, test series reports and even Pass/Fail labels, with or without barcodes, are available for printing.

Explosive, corrosive or other critical environments are no problem for MonTech rubber testing machinery. All instruments can be tailored to meet any international protection rating depending on what the customer

environment requires.

For a flexible instrument setup and utilization, MonTech offers movable instrument carts, fixed workbench carts and movable closed-instrument carts. Please contact us to discuss your individual instrument setup and space requirements to identify your ideal workplace scenario.

For a safe workplace free from smells and fumes, even when testing aggressive or hazardous materials, a forced ventilation and aspiration system can be fitted to every MonTech Mooney Viscometer.

MonTech offers a full range of precise reference standards and materials for Mooney Viscometers.

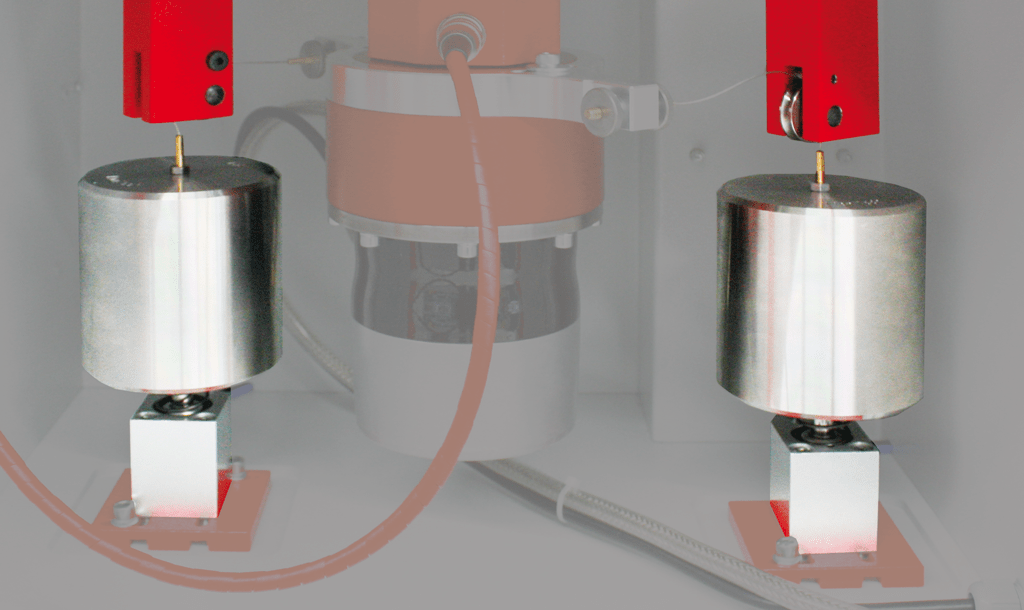

High precision calibration weight sets manufactured by MonTech are built into the instrument and controlled using a software guided calibration sequence, guaranteeing the highest accuracy and traceability for Mooney Viscometers.

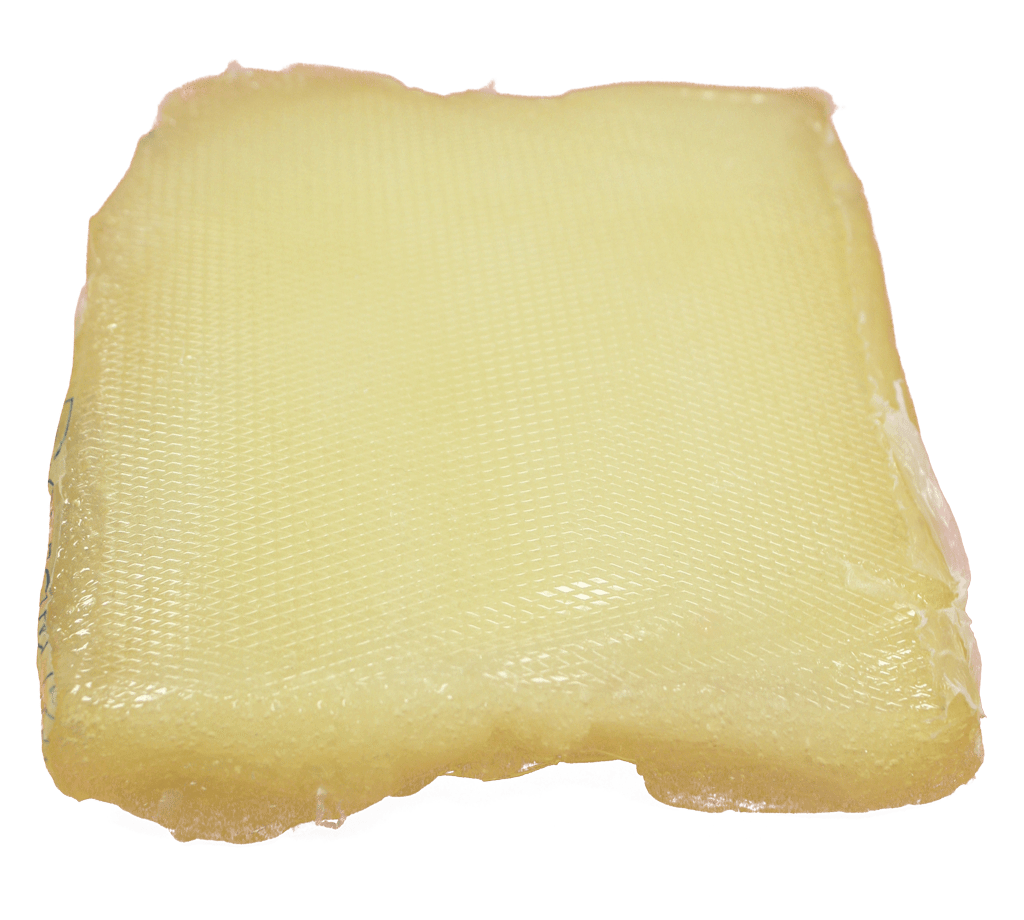

Precut reference butyl rubber for Mooney viscosity as well as stress relaxation verification allows easy verification and consistency checks on Mooney viscometers. Each supply includes a test certificate and interlab validation. Compound stability is typically good for up to 10 months.

Phone:

+49 (0) 6281 5622 30

Still not found what you're looking for?

MonTech rubber testing instruments are either available in standard versions or can be built according to individual customer requests and requirements. Contact us!