Rotor

Large (38.10 mm) and Small (30.48 mm) Sealed, with longlife seals

Rotor speed

2 turns per minute

Test modes

Mooney Viscosity,

Mooney Scorch,

Stress Relaxation,

Mould release,

Delta Mooney

Standard instrument for QC and R&D testing according to international standards.

Rotor

Large (38.10 mm) and Small (30.48 mm) Sealed, with longlife seals

Rotor speed

2 turns per minute

Test modes

Mooney Viscosity,

Mooney Scorch,

Stress Relaxation,

Mould release,

Delta Mooney

The Mooney Viscometer MV 3000 is the leading test instrument for measurement of viscosity, scorching and stress relaxation on polymers and rubber compounds.

The MV 3000 is suitable for quality control as well as research and development purposes with excellent repeatability and reproducibility due to its low-mass die design, direct heating and a unique direct drive design with snap-in mechanics.

The massive aluminium frame of the MV 3000 with its 270° accessible die area allows easy sample loading while integrated rotor ejection simplifies rotor handling. Operation is made easy by 4 illuminated pushbuttons providing clear information about the machine state. A motorized safety shield separates the die area before the test sequence is started.

Die temperatures are accurately and precisely measured by calibrated probes and controlled with a precision of +/- 0.03 °C by heaters, dies and rotors with an extremely fast thermal response.

The MV 3000 is fitted with built-in software-controlled systems for automatic balancing and calibration, including a double dead-weight system to apply a defined torque of 100 Mooney units, ensuring the utmost data accuracy and eliminating the needs of any external tools or fixtures.

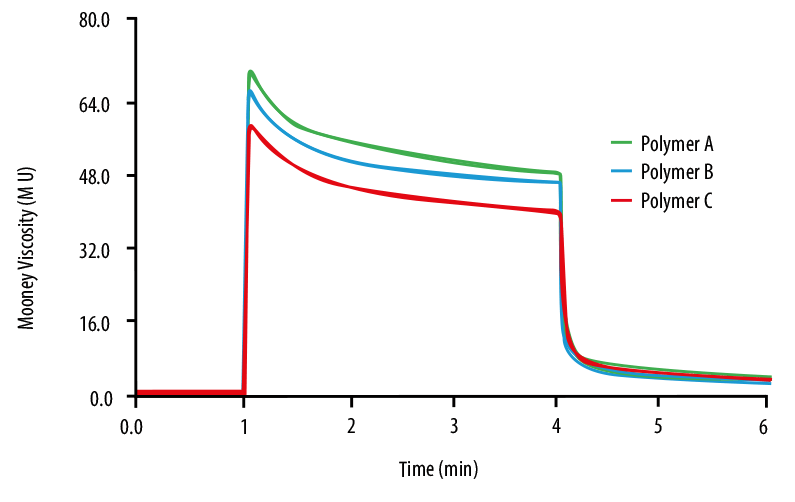

The Mooney Viscosity test is the most popular test method for characterizing polymers and uncured rubber materials. As defined by international standards, the sample material is preheated for a defined period in a closed die cavity, then sheared by the embedded rotor at a constant rate. The Mooney Viscosity is recorded and data is automatically calculated at predefined time and viscosity points. MonTech Mooney Viscometers offer superior precision and repeatability, providing the user with reliable data and making it easy to differentiate between different types and grades of polymers in order to ensure a high processing consistency.

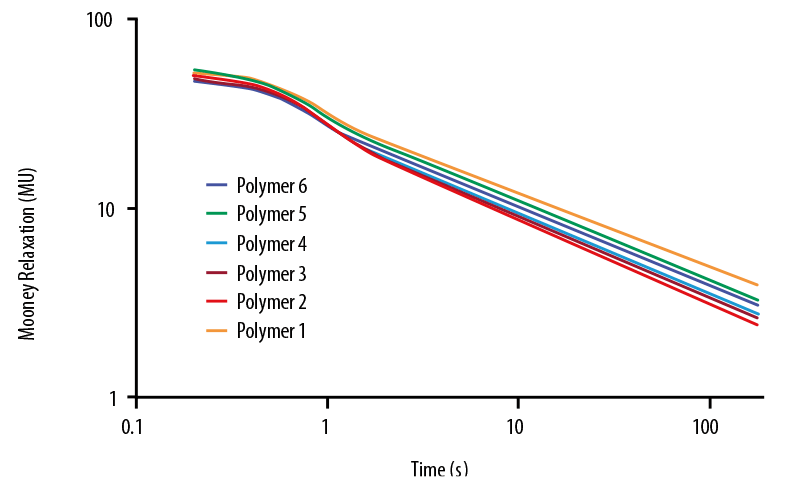

As Mooney Viscosity testing only provides information about the flow = viscosity of polymers and rubber compounds, stress relaxation testing can be used to assess elastic material behavior. This does not even require additional samples or testing efforts. Once the Mooney Viscosity test is completed, the rotor is stopped within 5 milliseconds and the torque decay is observed and recorded. Once the stress relaxation is completed, the slope-intercept and regression coefficient are calculated, providing excellent correlations in reference to polymer branching and processing.

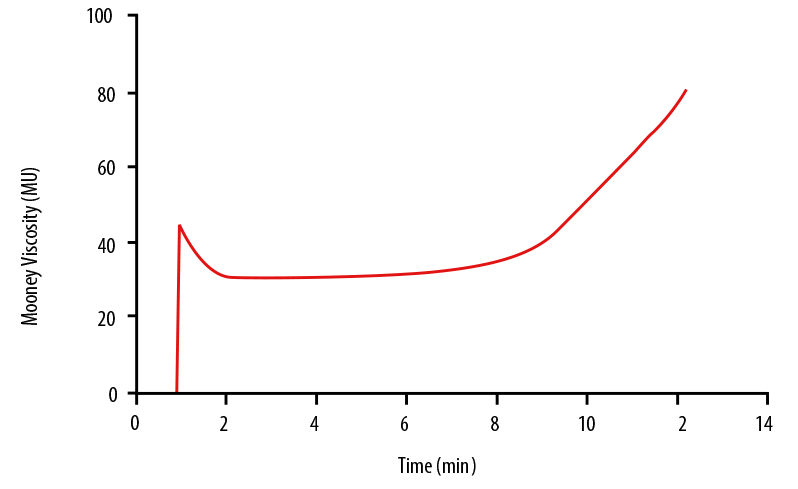

Mooney Scorch is one of the most useful tests to determine starting of cure - so called scorching behavior - of rubber compounds, providing essential data for designing and controlling production processes as well as checking material consistency. Of course, every MonTech Mooney Viscometer offers full Mooney Scorch and Delta Mooney testing capabilities featuring a selection of over 3500 datapoints which include initial Mooney viscosity, minimum viscosity, scorch times and scorch viscosities.

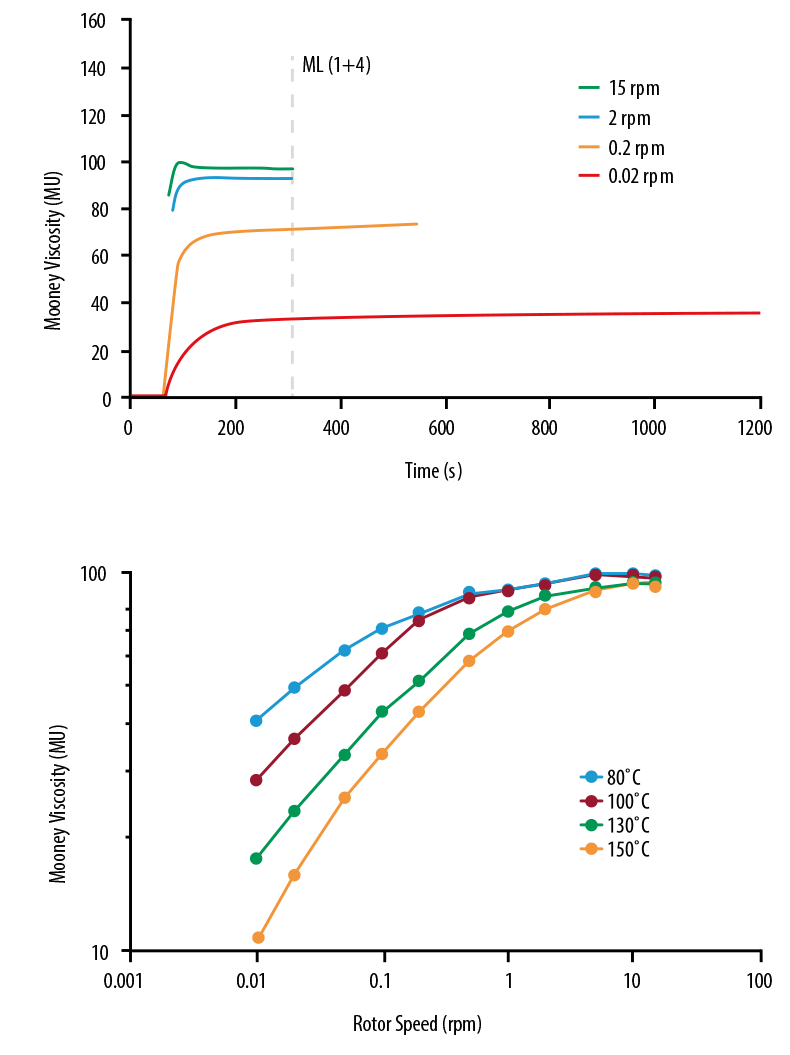

Besides only static testing, MonTech Variable Mooney Viscometers such as the V-MV 3000 offer full dynamic testing capabilities, allowing measurement of viscosity at variable shear rates (by stepless changes of the rotor speed) and temperatures. Furthermore, even non-isothermal sequences, variable rotor speed profiles as well as step-relaxations can easily be programmed and executed. Overall, this allows a detailed and complete understanding of the polymer behavior. Along with this, low rotor speed rates in Mooney Viscosity testing even provide the ability to test highly elastic and shear sensitive materials that could not be properly tested and characterized on Mooney Viscometers before.

ISO 289:2018, ASTM D 1646, DIN 53523, BS 903: Part 58, AFNOR T43-00/005, BS 1673, GOST 10722-76, JIS K6300, TGL 25-689

Mooney Viscosity, Mooney Scorch, Stress Relaxation, Mould release, Delta Mooney

Large (38.10 mm) and Small (30.48 mm) Sealed, with longlife seals

2.00 turns per minute (0.209 Radians / second)

According to ISO 289, DIN 53523 Part 4

Ambient to 232 °C, precision +/- 0.03 °C, digital, microprocessor controlled

Mooney - units (MU), Temperature (°C, °F), Time (min - min / min - sec)

11.5 kN

In-line torque transducer

Standard or longlife seals available

0.01 to 230 MU

Two specimens having a combined volume of 25 cm³

Recordings of the temperature gradient on the screen, PID microprocessor monitored

Fully automatic by built in calibration weights, Software guided

Ethernet (10/100 MBit), USB (int.), CF card (int.), RS232 (opt.)

Over 3500 data points available Including: Initial viscosity, ML / ML 1+X, Y+X+Z, Stress Relaxation (log-log), Slope, Intercept, Regression coefficient, Scorch viscosities and cure times

min. 4.5 Bar / 60 psi

200 V - 240 V, 6 Amps, 50/60 Hz

- Instrument control panel with 5“ touchscreen display and printer - Easy access and encapsulated electronic system - Rotor detection - Reinforced drive shaft and rotor to 300MU - Variable Rotor speed from 0.50 to 10.00rpm - Variable Rotor speed from 0.10 to 20.00rpm - Double channel forced air cooling system - Low-temperature cooling system MCool 10 - M-VS 3000 constant volume sample cutter Mooney Viscosity Mooney Scorch Stress Relaxation Calculated results 152 cm 60 cm 68 cm

The M-VS 3000 Mooney volumetric sample cutter enables higher accuracy, repeatability and optimized testing results in Mooney Scorch and Viscosity testing by preparing test samples with a constant volume. The M-VS 3000 also features automatic cutting of a center hole for the rotor shaft along with a time delay for compressing.

M-VS 3000Pneumatic cooling system

Lower radial v-groove die with large, serrated rotor

With our intelligent application and standard search you can find products for applications and DIN, ISO, ASTM, BS, AFNOR, JIS and TGL standards in a few seconds.