Oscillation strain

+/- 0.01° to 5°

Programmable via Software

MDR 3000

The MDR 3000 is the industry standard for measuring the viscoelastic properties of polymers and elastomeric compounds before, during and after cure. The acquired data is gives advanced information about processability, cure characteristics, cure speed, as well as the behavior of the compound after-cure at fixed, user selectable strain rates.

-

Instrument description

MDR 3000

Static testing

The MDR 3000 is the industry standard for measuring the viscoelastic properties of polymers and elastomeric compounds before, during and after cure. The acquired data is gives advanced information about processability, cure characteristics, cure speed, as well as the behavior of the compound after-cure at fixed, user selectable strain rates.

The instrument comes in the unique MonTech Series 3000 loadframe – industrial proof, fanless and ultra-rugged even for toughest production environments.

The reaction torque is measured by a high resolution, digital strain gauge assembly with integrated temperature compensation, making the MDR 3000 the most accurate and precise Moving Die Rheometer for static testing. Optionally, the instrument can be equipped with a combined torque / normal force sensor to assess blowing or sponging reactions of the tested material. For increased productivity and throughput, various types of highly reliable automation systems are also available.

Of course the MDR 3000 can be easily upgraded at a later stage to an MDR 3000 Professional to not only be able to run static but also dynamic test sequences.

Unique direct drive system

The instrument utilizes a direct, high-precision, gearless torque drive system mounted

directly to the lower die assembly. Therefore, the oscillation angle can be directly changed in the MonControl software, making the instrument capable of always measuring materials in the optimal strain range. This feature significantly reduces signal noise, improving the accuracy of testing results. With this fully digital drive system, no mechanical strain adjustments are needed and the motor positioning is monitored and recorded throughout the test.Automation options

All MonTech Moving Die Rheometers as well as Rubber Process Analyzers can be easily automated, allowing customers to increase productivity and release operators for other important tasks.

MonTech offers the worlds largest Rheometer Automation portfolio designed for our customers to rely on – in the lab or on the shopfloor, in multiple shifts, 365 days, every year. Depending on the selected type of automation system, samples are loaded and unloaded automatically from linear or rotary trays, film is fed and tested samples are removed automatically.

Of course, every automated machine can – within a single click – also be switched into manual operation mode.

Instrument options

For specific testing requirements MonTech offers a variety of instrument options to customize a testing solution exactly for your specific requirements:

– Forced air and low-temperature cooling systems

– Axial force transducers

– Cavity pressure control systems

– High speed data acquisition systems

– Data, IT and software integration

– Advanced productivity options -

Applications

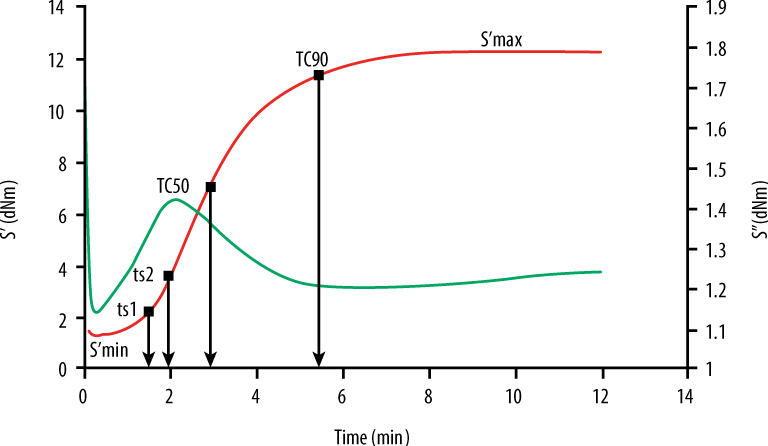

Isothermal Cure

Isothermal cure experiments are the most common type of test for quality control in rubber and elastomer processing. MonTech Moving Die Rheometers provide high precision data as well as a simple operation of the instruments. All the important characteristics, such as minimum / maximum elastic torque, scorch times, cure times and reaction rates are precisely calculated, with over 3500 different datapoints. All data is available in numerical as well as graphical form; limits, control gates and tolerance graphs can easily be set, and Pass / Fail status is automatically evaluated after each test.

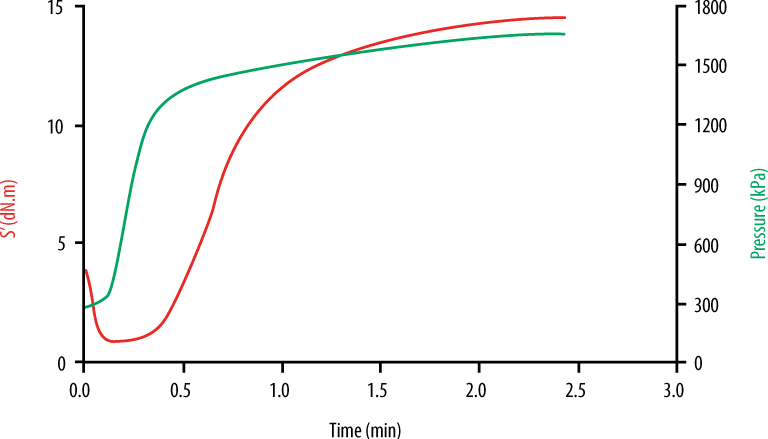

Cure with simultaneous Sponging / Foaming / Blowing Reaction

Especially for sealing applications, blowing agents form a vital part of compound recipes in order to produce a cellular structure via a foaming process that runs in parallel to the cure reaction. The cellular matrix structure which is created during the foaming process reduces density, increases thermal and acoustic insulation, and affects the relative stiffness of the mix. Therefore, MonTech Rheometers can be fitted with a precision normal force measurement transducer in the die cavity in order to calculate cavity pressure simultaneously during the curing and reaction in a single test, and revealing interrelations between the two reactions.

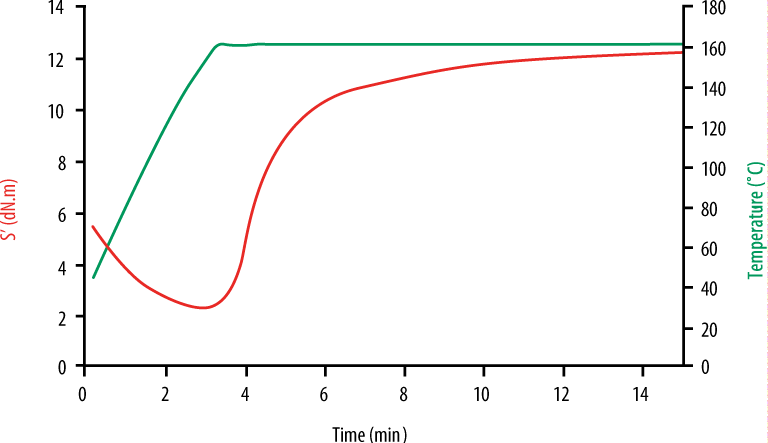

Non-isothermal Cure

In addition to isothermal static cure testing, MonTech MDRs and RPAs can perform tests at variable temperatures. These non-isothermal sequences can be programmed in order to follow virtually any temperature profile, making them especially valuable for the simulation of manufacturing processes which are usually not isothermal. Typical processes that can be simulated are mixing, milling, extrusion, compression moulding, injection moulding, and storage conditions. Of course, non-isothermal test sequences can be executed in a single test with any other static or dynamic sequence, such as strain and frequency sweeps, providing the most accurate data of the material‘s behavior at any production stage and material state.

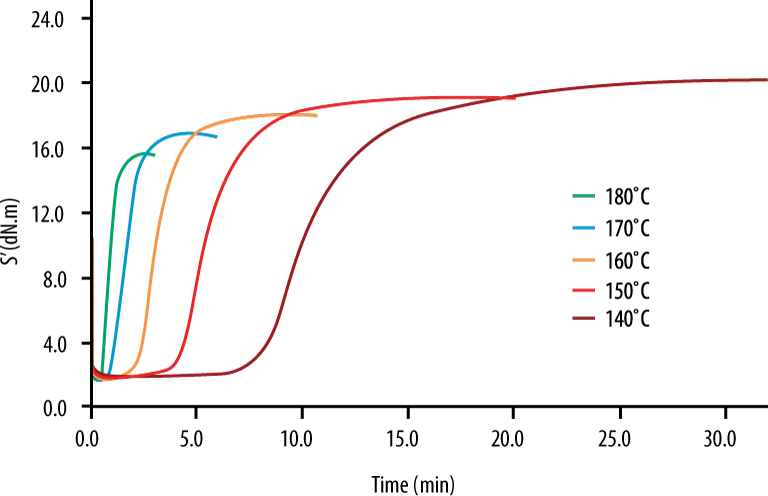

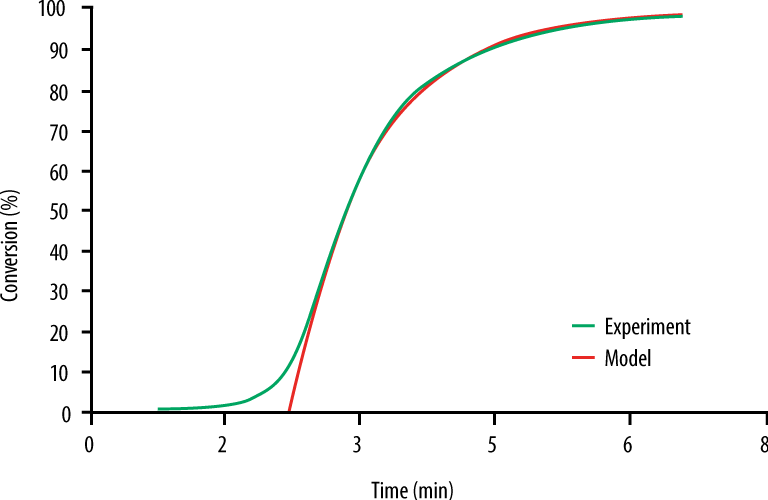

Advanced cure kinetics modeling

Test data from similar static or dynamic test sequences executed at different temperatures can automatically be evaluated and modelled for an advanced cure kinetics analysis, providing information about Reaction Rate, Order of Reaction (n), Rate Constant (k), Activation Energy (E) and Incubation Time (ti).

-

Technical Specification

Technical Specification

-

International standards

ISO 6502, ASTM D 5289, DIN 53529

-

Die configuration

Biconical, closed die system, sealed

-

Drive system

Direct, wearless servo drive system

-

Oscillation frequency

1.667 Hz (100 cpm)

-

Oscillation strain

+/- 0.01° to 5° (+/- 0.14% to 70%), Programmable via Software Optional “M” version with mechanically fixed oscillation angle

-

Temperature range

Ambient to 232 °C

-

Measured Data

Torque, temperature, frequency, strain Optional: Normal force

-

Calculated Data

S΄, S˝, S*, tan δ, phase angle, cure rate, ...

-

Die gap

0.45 mm nominal

-

Sample volume

approx. 4.5 cm³

-

Drive system

Direct, wearless servo drive system

-

Closing system

Soft closing to prevent foil rips and damage of test sample

-

Torque range

Ambient to 232 °C

-

Temperature control system

Ambient to 232 °C, precision +/- 0.03 °C, Max. heating rate: 85°C/min digital, microprocessor controlled

-

Temperature check system

Recordings of the temperature gradient on the screen, microprocessor monitored

-

Data Interface

Ethernet (10/100 MBit), USB (int.), CF card (int.), RS232 (opt.)

-

Data points

Over 3500 data points available for each test; Including S‘ Min, S‘ Max, TS 1, TS 2, TC 10, TC 30, TC 50, TC 90

-

Pneumatics

min. 4.5 Bar / 60 psi

-

Electrical

200-240 V, 6 Amps, 47-63 Hz, Single phase

-

Instrument options

- “M” version with mechanical drive system - Instrument control panel with 5“ touchscreen display and printer - Adapted transducers for high or low-viscosity torque range - Normal force / Pressure measurement - Double channel forced air cooling system - Extended thermal range to +300°C - Autoloader 5 or 10 sample linear - Autoloader with 24, 48 or 100 sample tray or tray changers - R-VS 3000 constant volume sample cutter - Label Printer - Signal tower

Calculated results

Parameter

Size Ratio

-

-

Options

VS 3000

The VS 3000 universal constant volume cutter is the ideal and reliable sample preparation tool for applications that require constant volume samples such as preforms for moulding operations. The VS 3000 sample cutter can be fitted with knives of any diameter between 20 and 60mm per customer requirements, making the cutter an ideal tool for easy preform preparation in lab or production environments.

VS 3000

High volume vacuum handling of samples guarantee proper sample handling and placement.

Safe, reliable and automated sample removal and film advancement.

Specific Standard and Application Search

With our intelligent application and standard search you can find products for applications and DIN, ISO, ASTM, BS, AFNOR, JIS and TGL standards in a few seconds.