Rotor speed

2 turns per minute

MV 3000 Basic

A rotational shear viscometer according to Mooney for performing Viscosity tests (ML / MS 1+X), Stress Relaxation testing, Mooney Scorch, Delta Mooney testing on polymers as well as rubber compounds for quality control, research and development applications.

-

Instrument description

MV 3000 Basic

Entry level Mooney Viscometer

The MV 3000 Basic is a rotational shear viscometer according to Mooney for performing

– Viscosity tests (ML / MS 1+X)

– Stress Relaxation testing

– Mooney Scorch

– Delta Mooney testingon polymers as well as rubber compounds for quality control, research and development applications.

The MV 3000 Basic is supplied as a complete, ready-to-test instrument set including a personal computer, MonControl Software, cables, connectors and regulators as well as a standard set of tools and consumables.

Easy to use:

All test parameters are pre-programmed through the MonControl Software – the instrument is equipped with a single button for starting the test sequence.Direct feedback:

An integrated multi-color LED status bar clearly displays the current machine state.Rugged:

The compact and highly rigid frame is made from high strength aluminum. Along with direct-drive technology, this guarantees stable and accurate test results in every environment.Rotor, die assembly and drive system

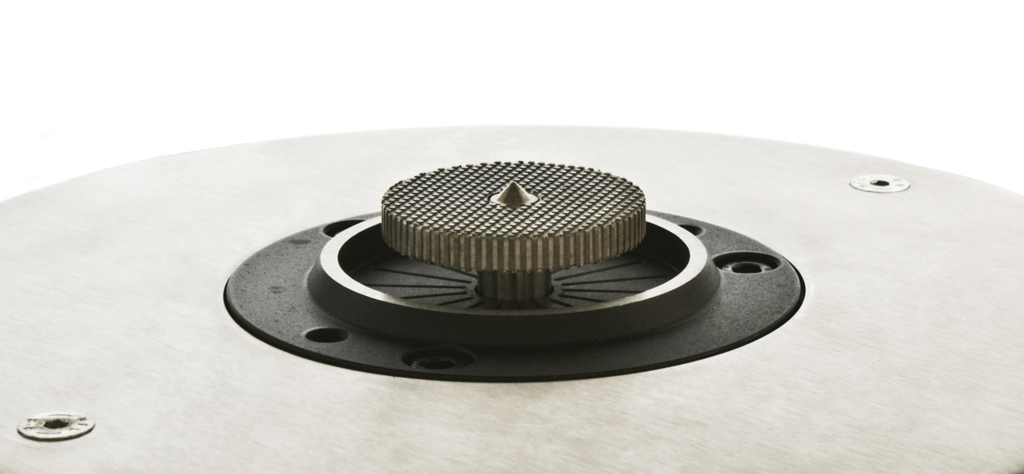

The most fundamental and important parts on a Mooney Viscometer are the rotor, die assembly and in-line drive shaft. The test sample is placed below and above the rotor with optional test film. Then the upper die is lowered onto the lower die with a force of 11.5 kN.

After a pre-heat time, the rotor – which is now totally embedded in the test material in the closed die cavity – rotates at a fixed speed of 2 turns per minute, powered by an in-line drive system.

During the whole test sequence, the temperatures of both dies are measured by a separate precision probe on each die and the heaters are accordingly controlled and regulated to precisely maintain the temperature at its setpoint.

The torque needed to turn the rotor in the test material is precisely measured by an in-line torque transducer. Torque in Mooney Units (MU), die temperatures and rotor speed are recorded. Data is automatically calculated and displayed once the test is completed.

-

Applications

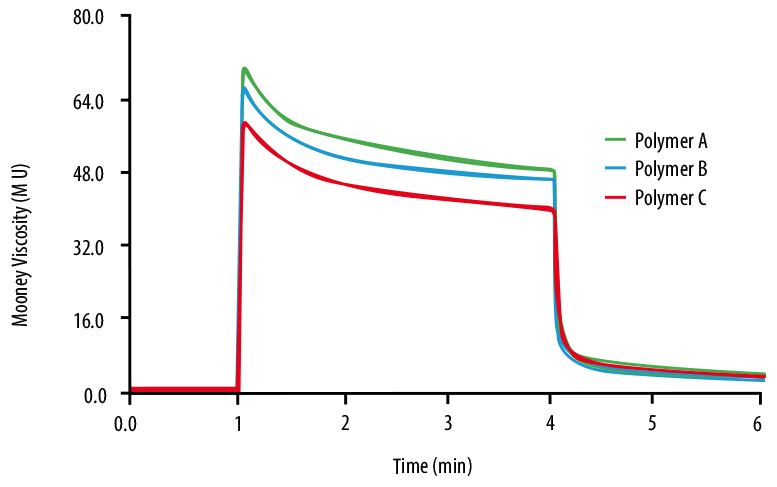

Mooney Viscosity

The Mooney Viscosity test is the most popular test method for characterizing polymers and uncured rubber materials. As defined by international standards, the sample material is preheated for a defined period in a closed die cavity, then sheared by the embedded rotor at a constant rate. The Mooney Viscosity is recorded and data is automatically calculated at predefined time and viscosity points. MonTech Mooney Viscometers offer superior precision and repeatability, providing the user with reliable data and making it easy to differentiate between different types and grades of polymers in order to ensure a high processing consistency.

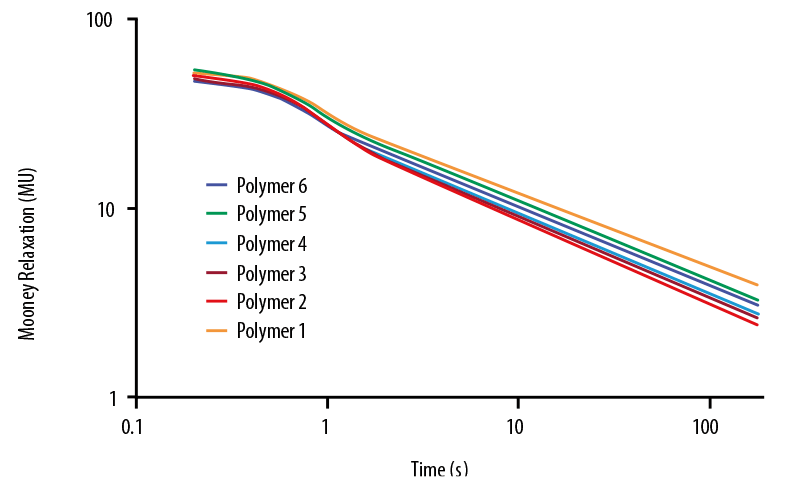

Mooney Stress Relaxation

As Mooney Viscosity testing only provides information about the flow = viscosity of polymers and rubber compounds, stress relaxation testing can be used to assess elastic material behavior. This does not even require additional samples or testing efforts. Once the Mooney Viscosity test is completed, the rotor is stopped within 5 milliseconds and the torque decay is observed and recorded. Once the stress relaxation is completed, the slope-intercept and regression coefficient are calculated, providing excellent correlations in reference to polymer branching and processing.

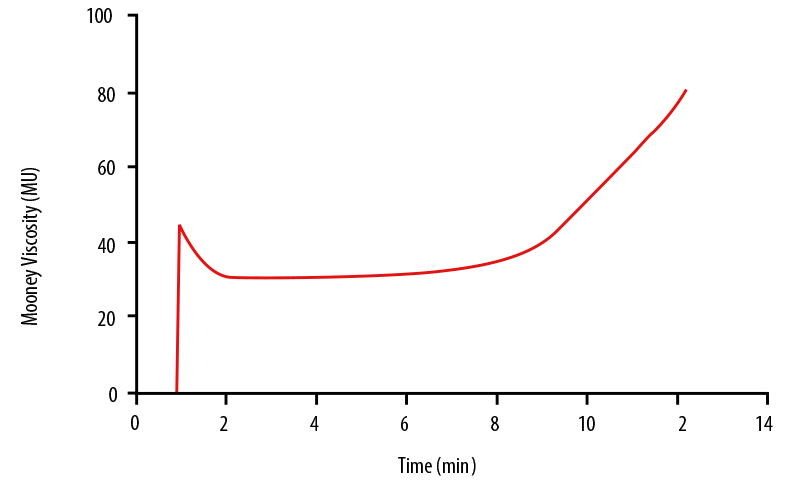

Mooney Scorch

Mooney Scorch is one of the most useful tests to determine starting of cure - so called scorching behavior - of rubber compounds, providing essential data for designing and controlling production processes as well as checking material consistency. Of course, every MonTech Mooney Viscometer offers full Mooney Scorch and Delta Mooney testing capabilities featuring a selection of over 3500 datapoints which include initial Mooney viscosity, minimum viscosity, scorch times and scorch viscosities.

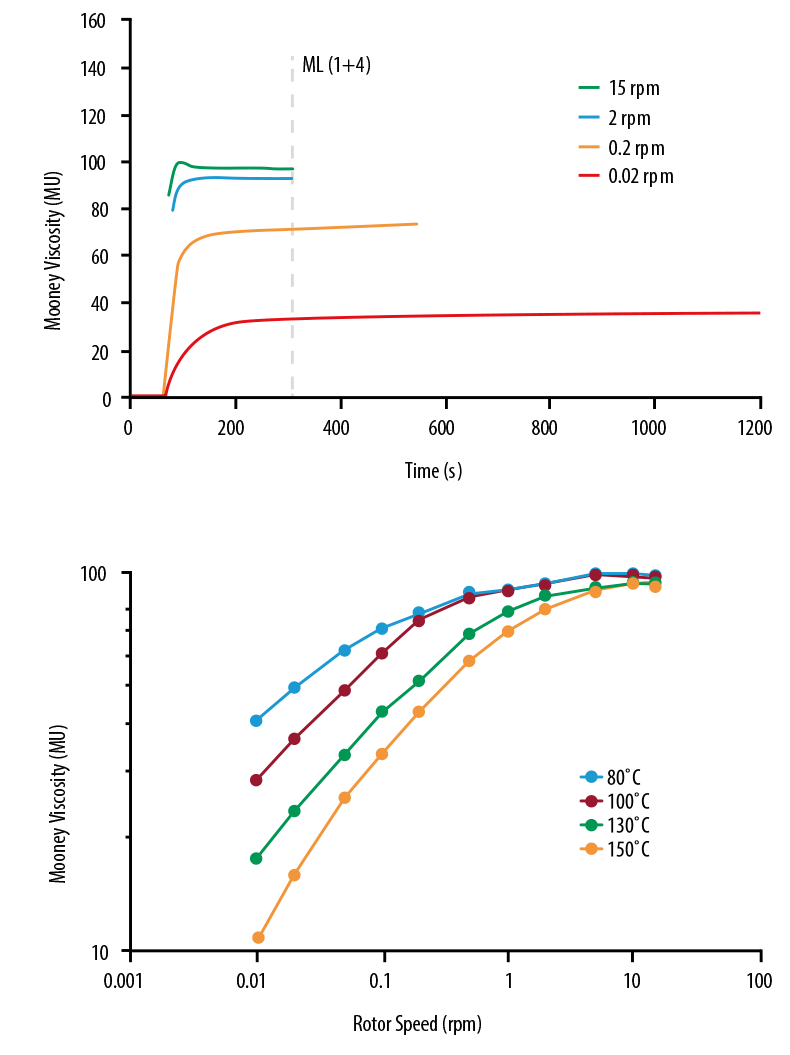

Mooney Viscosity at Shear Rates and Temperatures

Besides only static testing, MonTech Variable Mooney Viscometers such as the V-MV 3000 offer full dynamic testing capabilities, allowing measurement of viscosity at variable shear rates (by stepless changes of the rotor speed) and temperatures. Furthermore, even non-isothermal sequences, variable rotor speed profiles as well as step-relaxations can easily be programmed and executed. Overall, this allows a detailed and complete understanding of the polymer behavior. Along with this, low rotor speed rates in Mooney Viscosity testing even provide the ability to test highly elastic and shear sensitive materials that could not be properly tested and characterized on Mooney Viscometers before.

-

Technical Specification

Technical Specification

-

International standards

ISO 289:2018, ASTM D 1646, ASTM D 3346, DIN 53523, BS 903: Part 58, AFNOR T43-00/005, BS 1673, GOST 10722-76, JIS K6300, TGL 25-689, ...

-

Test modes

Mooney Viscosity, Mooney Scorch, Stress Relaxation, Mould release, Delta Mooney

-

Rotor

Large (38.10 mm) and Small (30.48 mm) Sealed, with longlife seals

-

Rotor speed

2.00 turns per minute (0.209 Radians / second)

-

Stress Relaxation

According to ISO 289, DIN 53523 Part 4

-

Temperature control system

Ambient to 232 °C, precision +/- 0.03 °C, digital, microprocessor controlled

-

Units

Mooney - value (MU) | Temperature (°C, °F) | Time (min - min / min - sec / sec)

-

Closing force

11.5 kN

-

Die configuration Rotor

According to international standards large (ø 38.1 mm) and small (ø 30.48 mm) Rotor

-

Force measurement

In-line torque transducer

-

Rotor shaft seal

Standard or longlife seals available

-

Torque range

0.01 to 230 MU

-

Sample volume

Two specimens having a combined volume of 25 cm³

-

Machine frame

Rugged 4 column frame with 4 stable posts - Large post distance for easiest access to test dies for sample loading, cleaning and maintenance - Pre-tensioned tiebars for highest rigidity avoiding any frame deformation under load - Integral crosshead with guiding on all 4 posts for precision parallel closing of test dies - Intelligent die alignment by special coupling of main cylinder to moving crosshead ensuring perfect and uniform pressurized sealing of test test7 - Symmetrical alignment due to auto-alignment feature, mechanical and thermal symmetrical frame compensating for non-compliance ensuring highest precision of test results

-

Temperature check system

Recordings of the temperature gradient on the screen, PID microprocessor monitored

-

Calibration

Fully automatic by built in calibration weights, Software guided

-

Data Interface

Ethernet (10/100 MBit), USB (int.), CF card (int.), RS232 (opt.)

-

Data points

Over 3500 data points available Including: Initial viscosity, ML / ML 1+X, Y+X+Z, Stress Relaxation (loglog), Slope, Intercept, Regressions coefficient, Scorch viscosities and cure times

-

Pneumatics

min. 4.5 Bar / 60 psi

-

Electrical

Single phase 100 - 120 V, 8 Amps or 200 V - 240 V, 5 Amps

-

Instrument options

- Instrument control panel with 5“ touchscreen display and printer - Variable Rotor speed from 0.50 to 10.00rpm - Variable Rotor speed from 0.00 to 20.00rpm - Rotor detection - Double channel forced air cooling system - Low-temperature cooling system MCool 10 - M-VS 3000 constant volume sample cutter - Label Printer - Signal tower

Calculated results

PARAMETER

Size Ratio

-

-

Options

M-VS 3000

The M-VS 3000 Mooney volumetric sample cutter enables higher accuracy, repeatability and optimized testing results in Mooney Scorch and Viscosity testing by preparing test samples with a constant volume. The M-VS 3000 also features automatic cutting of a center hole for the rotor shaft along with a time delay for compressing.

M-VS 3000

Specific Standard and Application Search

With our intelligent application and standard search you can find products for applications and DIN, ISO, ASTM, BS, AFNOR, JIS and TGL standards in a few seconds.