Moving Die Rheometer

Moving Die Rheometers are the standard testing method for characterisation of rubber curing in quality control as well as research and development.

Moving Die Rheometers are the standard testing method for characterisation of rubber curing in quality control as well as research and development.

Mooney Viscometers are the backbone for testing the viscous flow of raw materials such as polymers and intermediates such as masterbatches for maintaining stable and consistent manufacturing processes.

The laboratory bale cutters provides the most convenient solution to cut and slice polymers bales, blocks and rubber sheets.

Carbon black dispersion tester – Computer aided, advanced digital reflected light microscopy brought to the next level.

Test instrument for measurements of the density of rubber mixtures.

State of the art fatigue testing and lifecycle simulation instrument.

Test instrument for measurements of the shore hardness and the density of rubber mixtures.

MonTech offers a wide range of sample cutters equipment for every need.

The most advanced and fully automated testing solution for high capacity mixers

Automatic Schob pendulum impact elasticity tester for elastomers and foams

The MonTech Rapid Plastimeter measures the plasticity, flow and viscosity of polymers and unvulcanized rubbers. The instrument is typically used in conjunction with the MonTech Ageing oven AO 3000 for plasticity testing to determine the Plasticity Retention Index (PRI) of raw natural rubbers.

Compression set fixtures enable measurements of a rubber compound’s ability to return to its original thickness after prolonged compressive stresses.

MonTech offers a wide range of sample cutters and specimen preparation equipment for every need.

The MonTech VP 3000 and LP 3000 are specifically designed for rubber applications and have evolved into the international standard in laboratory presses in the rubber industry.

Product

Brochures

Moving Die Rheometers are the standard testing method for characterisation of rubber curing in quality control as well as research and development.

Compact, entry model instrument for repetitive quality control testing as well as simple R&D applications.

DetailsThe MDR 3000 is the industry standard for measuring the viscoelastic properties of polymers and elastomeric compounds before, during and after cure. The acquired data is gives advanced information about processability, cure characteristics, cure speed, as well as the behavior of the compound after-cure at fixed, user selectable strain rates.

DetailsEntry model instrument in the Rubber Process Analyzer (RPA) technology. The MDR 3000 Prof. can be operated either in static testing mode (MDR) or also in dynamic testing mode (RPA).

DetailsHigh-end instrument for demanding static and dynamic testing in QC and R&D with a huge set of customizing options. This enables testing capabilities that have not been possible to measure in a Rheometer before, such as die gap regulation, High-speed data acquisition (FT-Rheology), low-temperature cooling, …

DetailsTop model for advanced dynamic testing of all kinds of rubber, rubber-like, curing or crosslinking materials. This includes TPE, TPV, LSR, Composite materials, Polyolefins, ...

DetailsMoving Die Rheometer

(MDR and RPA) Series

Moving Die Rheometers are the standard testing method for characterisation of rubber curing in quality control as well as research and development.

Therefore these rotorless curemeters are equipped with a closed, sealed, biconical die system according to all relevant ISO, ASTM and DIN standards. During the test the lower die performs a sinusoidal oscillation with a fixed oscillation amplitude and frequency, at either a fixed (isothermal) or variable temperature (non-isothermal).

MonTech Moving Die Rheometer systems are the backbone for reliable and repeatable quality control in the rubber industry – offering a unique design with an extremely rigid test frame and superior temperature control.

Depending on the instrument model, the instrument is either equipped with a mechanical or with a direct drive system. Every machine is supplied with the flexible and easy to operate MonControl Software for managing test specifications, acquiring data, and reporting results.

Furthermore, every instrument can be configured to exactly meet the customers specific needs – this includes a modular platform of automation solutions, cooling options and sample preparation systems.

PDF Download

The machine frame of every MonTech Rheometers is constructed from aerospace grade aluminum and stainless steel making MonTech Rheometers the most rugged and stable Rheometer systems in the market. This design includes baseplates of up to 80 mm thickness, 50 mm stainless steel pullrods, massive 80 mm crossheads with integral stainless steel force crossbeam support for superb die symmetry and alignment as well as and up to 20 mm thick side panels. This results in an overall superior instrument stiffness; significantly improving repeatability and result correlation, while reducing signal-to-noise ratio as well as guaranteeing the best damping abilities, especially for high frequency testing and unbeaten dynamic testing performance.

This ultra-rigid instrument design has even more advantages: The whole instrument frame is used as a heatsink for all major electronic components so that the instrument does not need any fans or air ventilation for cooling, allowing the complete electronic cabinet to be sealed against pollution and especially conductive carbon black dust.

As only high-strength aluminum and stainless steel are used for every single component in the instrument, corrosion is no issue at all, making MonTech instruments a secure investment.

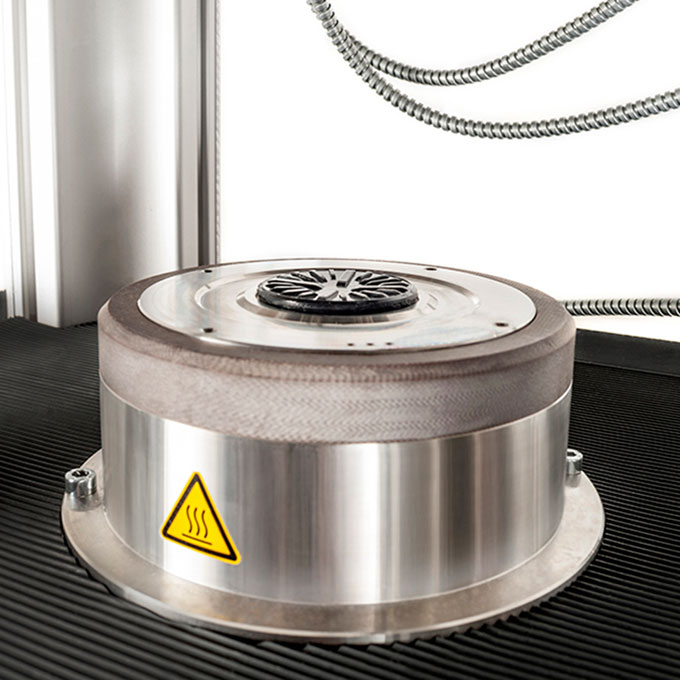

MonTech Moving Die Rheometers are equipped with a biconical die assembly with integrated direct heating, accurate sample temperature measurement, superior temperature control with unbeaten accuracy, highest heating and cooling rates, and minimized response times. The specific die and crosshead design ensures a perfect alignment and uniform closing as well as parallelism of both test dies, significantly reducing result variations. MonTech Rheometer test dies are entirely made from superior, lot-traceable stainless steel, hardened, precision ground and polished, making the dies built to last with an extreme stiffness and durability even against the most abrasive rubber compounds.

The test dies are sealed off with easily changeable long-life seals to provide superior lifetimes of up to 12 months, minimizing maintenance and instrument downtime.

Every MonTech Rheometer is equipped with a pneumatic die closing system for a reliable closing and sealing of the die cavity. Optionally, instruments can be equipped with variable closing force, cavity pressure and variable die gap control. In combination with the MonTech loadframe, this instrument design guarantees compliant testing results at the highest possible level of accuracy and precision paired with perfect reproducibility and reliability.

MonTech Instruments feature internal diagnostic and condition monitoring routines for every critical process, enabling the instrument to detect, report and even solve problems before they occur.

Along with MonTech precision calibration tools, customers are guided through a software sequence, making the verification of the instrument really easy in order to always guarantee the highest instrument precision and most accurate test data. Once the verification process is completed, a detailed PDF Report with all critical verification and calibration is generated, assuring traceability to any reference standard used. Readings of most reference standards and performance parameters are taken by the software, minimizing operator involvement for providing objective results.

Torque / force transducers and loadcells are the most critical part when it comes to precision of the instrument because raw torque and force signals, as well as derived modulus and viscosity signals are directly used for test result calculation. This is exactly the reason why MonTech designs and manufactures all transducers in-house. This guarantees the widest measurement ranges along with clean-room applied strain gauge technology paired together in ultra-rugged and stiff assemblies.

MonTech's intelligent transducer technology possesses various unique features such as variable amplifications, stiffness control and temperature compensation — proof again that MonTech systems are the most advanced testing systems available; guaranteeing the highest accuracy and precision from the smallest Milli-Newton torque readings to the highest dynamic loads over the complete torque range.

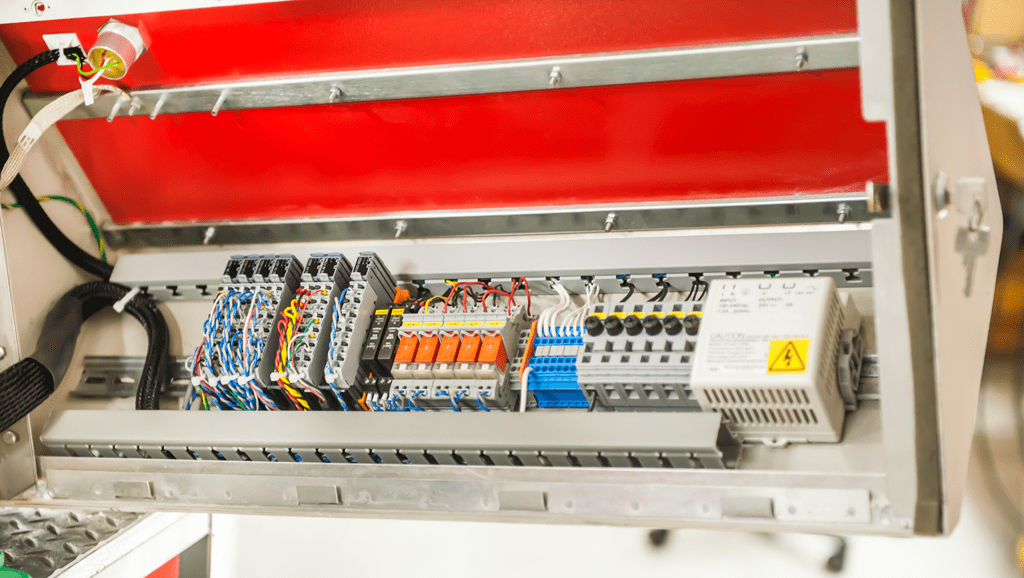

Programmable Logic Controllers form the backbone of every MonTech testing instrument, providing customers with proven technology and the highest system reliability.

The highly complex set of stress, strain and other raw data streams and results that are all time-critical to each other are analyzed in real-time with the most advanced 24-bit electronics and a 10 kHz high speed data sampling rate. This superior oversampling technology paired with the superior signal to noise ratio eliminates the need for data filtering or further data processing, providing the user with actual true measured data and results. MonTechs advanced rubber testing machines support customers with as much valuable material information as possible, with features including measurement of higher harmonics, nonlinearities, and behavior at extreme processing conditions.

Every MonTech Rheometer and Mooney Viscometer is equipped with a rugged, well-proven and reliable Programmable Logic Controller (PLC) system as well as standard automation components. Every instrument is directly equipped with an Ethernet interface, allowing direct integration of the machine into the customers network as well as linking host systems and computers by standard TCP/IP protocol with extremely high

data rates and throughput.

MonTech Rheometer systems are equipped with the latest, closed-loop digital drive technology. The quality and performance of the instruments‘ rheological measurements are highly influenced by the precision of the applied deformation and thus the motor positioning. Therefore all Rheometer testing systems are equipped with the latest high-precision drive systems:

The MDR 3000 Basic instrument features a geared, brushless DC motor with integrated drive control systems, digitally connected to the instrument PLC unit, making this drive the ideal system for static testing at fixed frequencies.

All other MonTech Moving Die Rheometers and Rubber Process Analyzers feature the patented MonTech wearless direct torque drive system which ensures highly precise, stepless, and variable movement of strains, frequencies and other types of controlled sequences. This unique and powerful drive is the only motor system that has been specially designed for MDR and RPA applications. Unbeaten dynamic performance can be achieved as the drive is mounted directly underneath the lower die, minimizing the moving mass and eliminating the need of any clutches, drive shafts or couplings. Finally, this means that there are absolutely no start delay for backlashes, continuously assuring exact and repeatable movements for the most accurate rheological measurements. Ceramic and magnetic bearings form the backbone of the drive‘s high durability, stiffness, rigidity and reliability, resulting in superior precision for the smallest strains to the highest frequencies. In-line to the main drive system, a specially designed high-precision angular displacement sensor with an accuracy of 0.000001° is mounted, measuring the slightest movements and forming a digital, closed-loop control circuit with a response time of less than 20 nanoseconds.

MonTech Moving Die Rheometers are the world-leading instrument series for reliable cure measurements in the rubber industry.

Due to the rugged design and superior design quality, MonTech instruments clearly offer superior accuracy and precision, proven by our certifications and accreditations including ISO 9001:2008 and ISO/IEC 17025:2005.

These calibrations services are offered throughout the world by our highly qualified team of MonTech field engineers in order to make sure that the calibrations of your instruments are fully traceable and comply to all local, company, and international standards.

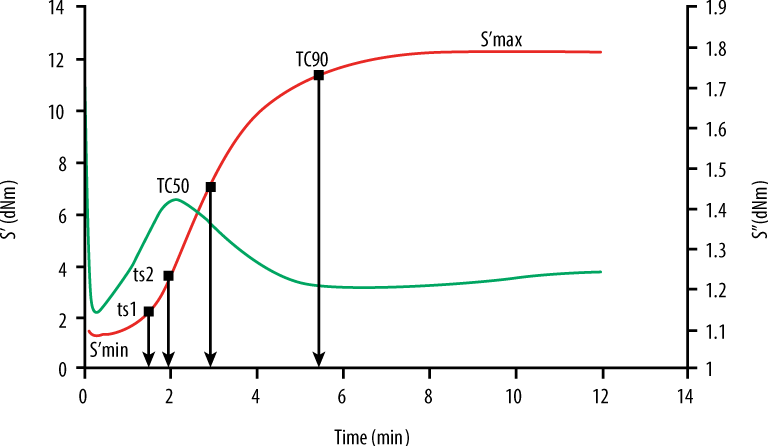

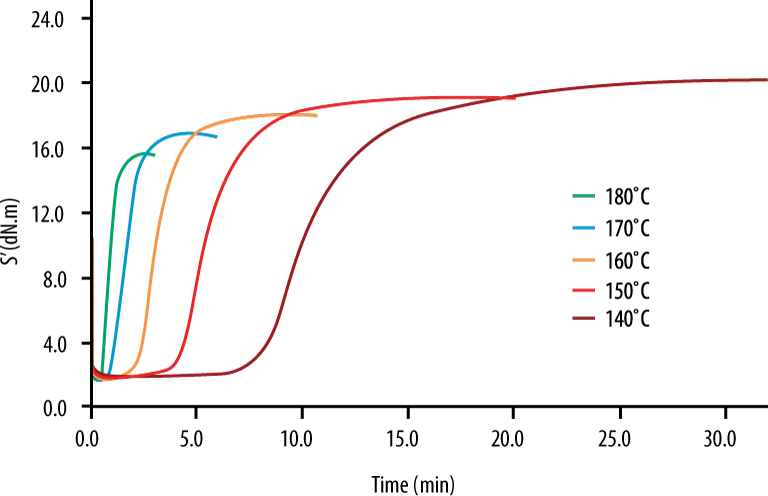

Isothermal cure experiments are the most common type of test for quality control in rubber and elastomer processing. MonTech Moving Die Rheometers provide high precision data as well as a simple operation of the instruments. All the important characteristics, such as minimum / maximum elastic torque, scorch times, cure times and reaction rates are precisely calculated, with over 3500 different datapoints. All data is available in numerical as well as graphical form; limits, control gates and tolerance graphs can easily be set, and Pass / Fail status is automatically evaluated after each test.

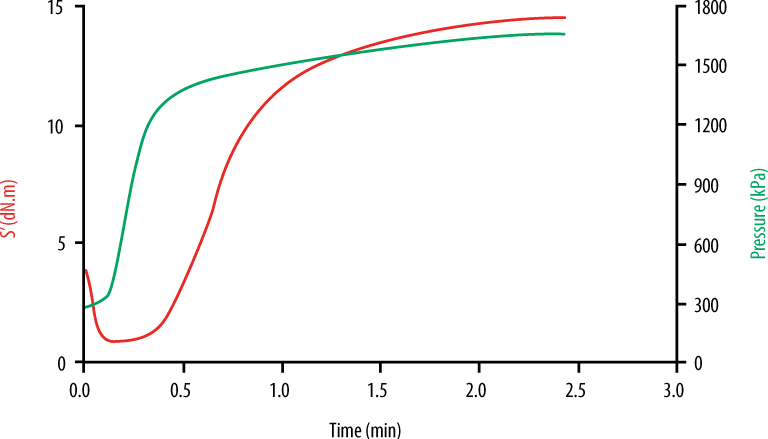

Especially for sealing applications, blowing agents form a vital part of compound recipes in order to produce a cellular structure via a foaming process that runs in parallel to the cure reaction. The cellular matrix structure which is created during the foaming process reduces density, increases thermal and acoustic insulation, and affects the relative stiffness of the mix. Therefore, MonTech Rheometers can be fitted with a precision normal force measurement transducer in the die cavity in order to calculate cavity pressure simultaneously during the curing and reaction in a single test, and revealing interrelations between the two reactions.

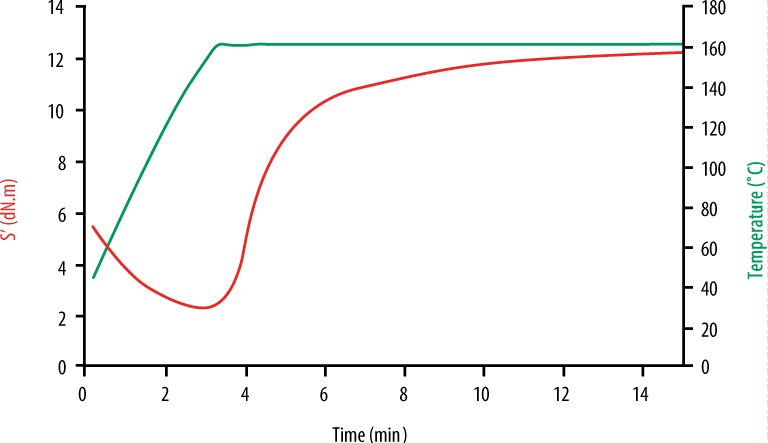

In addition to isothermal static cure testing, MonTech MDRs and RPAs can perform tests at variable temperatures. These non-isothermal sequences can be programmed in order to follow virtually any temperature profile, making them especially valuable for the simulation of manufacturing processes which are usually not isothermal. Typical processes that can be simulated are mixing, milling, extrusion, compression moulding, injection moulding, and storage conditions. Of course, non-isothermal test sequences can be executed in a single test with any other static or dynamic sequence, such as strain and frequency sweeps, providing the most accurate data of the material‘s behavior at any production stage and material state.

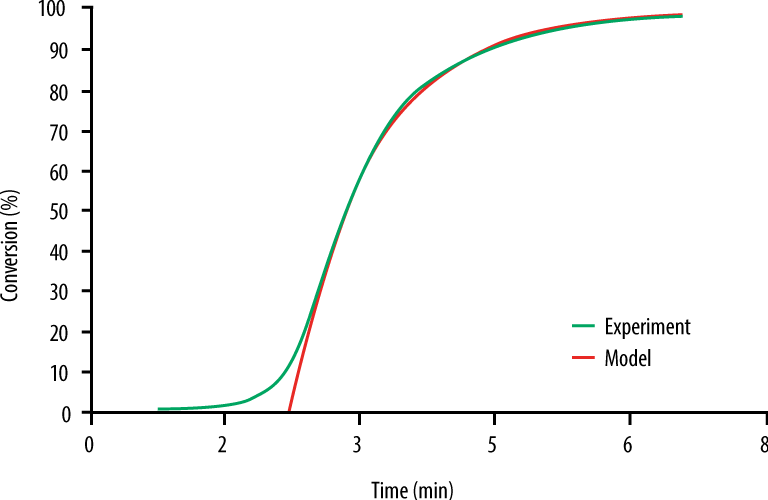

Test data from similar static or dynamic test sequences executed at different temperatures can automatically be evaluated and modelled for an advanced cure kinetics analysis, providing information about Reaction Rate, Order of Reaction (n), Rate Constant (k), Activation Energy (E) and Incubation Time (ti).

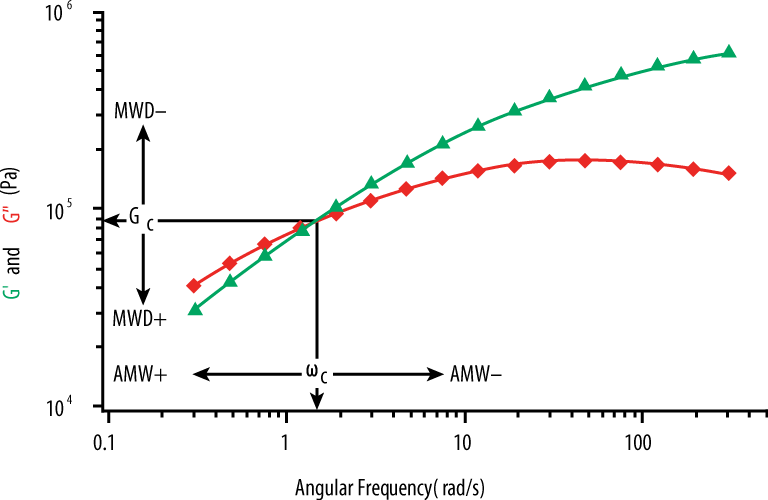

In general, the mechanical properties of materials depend on frequency. A good under-standing of the influence of frequency on a material is therefore very important for its practical use. For example, a material appears stiff under the action of a force at high frequency, but soft when the force is applied slowly. Isothermal frequency sweeps provide information about the weight distribution MWD (crossover modulus) as well as average molecular weight AWM (crossover frequency). But the behavior of viscoelastic materials like polymers not only depends on frequency, it also depends on temperature. MonTech has incorporated further advanced testing capabilities such as the Time-Temperature Superposition principle (TTS), which is based on the equivalence between frequency and temperature behavior during transition processes, forming the basis of WLF master-curve modelling available on MonTech dynamic Rheometers, even for predicting material performance at frequencies outside the range that can be measured with a dynamic mechanical analyzer.

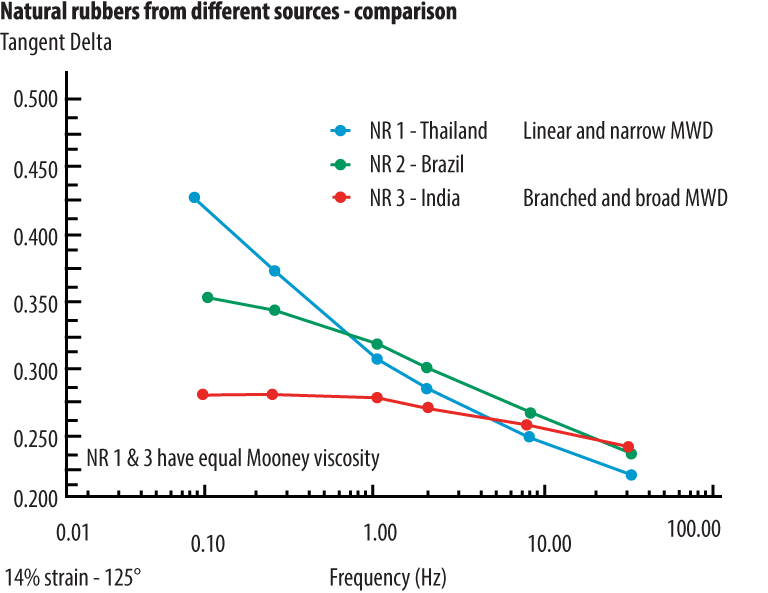

The rheological properties of rubbers are related to their structural characteristics and will influence the behavior of the rubber during processing and the performance of the final product. While Mooney testing does not provide sufficient information to clearly differentiate branching and Molecular weight distribution the Rubber Process Analyzer can easily be used as a tool for solving production problems. Using frequency sweeps to scan the material over the whole shear rate range can reveal substantial material

differences and variations e.g. causing a particular material to be very sticky and therefore difficult to process while others can be perfectly processed.

These test can be performed in the linear and also non-linear viscoelastic range to cover all different processing methods and material states. ISO 13145 suggests a simple and quick test procedure utilising a rotorless sealed shear rheometer (RPA) for rheological evaluations as an alternative to traditional Mooney Viscometer testing.

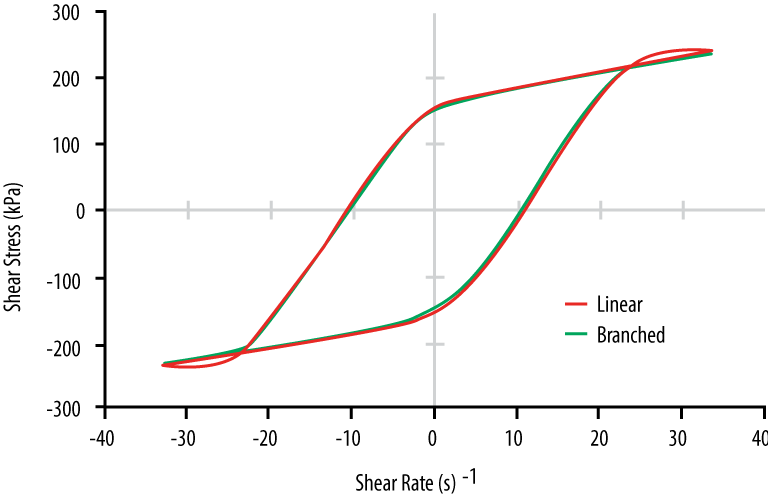

Dynamic oscillatory shear tests are common in rubber rheology - more specifically, small-amplitude oscillatory shear (SAOS) tests are the most common test method for measuring linear viscoelastic properties of rubber compounds and polymers.

But in processing operations, the shear rates can be large and rapid; non-linear material properties form an even more important part in understanding material response. Therefore, MonTech Rheometers provide Fourier transformation analysis capabilities of periodic data, along with full raw-data access, for in-depth analysis to investigate and quantify the nonlinear viscoelastic behavior by using large-amplitude oscillatory shear (LAOS) testing in order to characterize and quantify material stress response which is no longer purely sinusoidal (linear), allowing a better understanding of filler content and structure, as well as the polymer architecture.

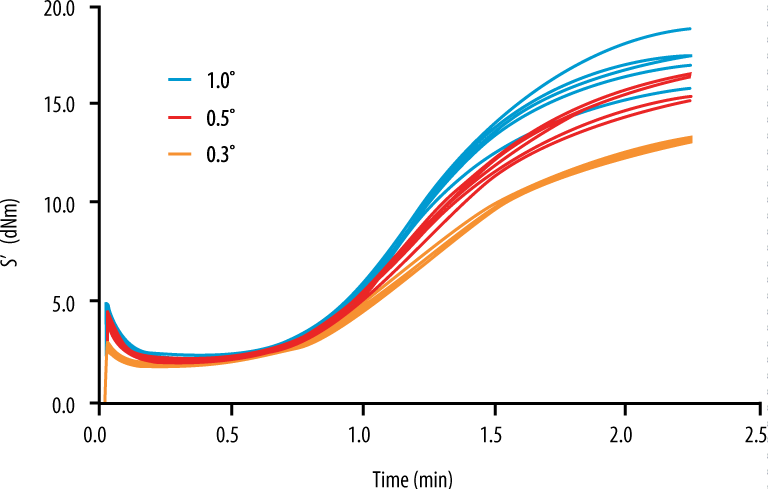

Typically, cure experiments on rubber compounds - especially for quality control purposes - are performed with a fixed oscillation angle of +/- 0.5° and a frequency of 1.67 Hz. However, for specific rubber compounds or challenging materials such as silicones or epoxy resins, this might not be ideal as either reaction torque readings are too low, providing only a limited ability to distinguish between different batches, or might be too high causing high result variability as the material is damaged as strain already exceeds the linear viscoelastic range. MonTech Rheometers provide the possibility of testing with variable oscillation angles to allow measurements within the ideal strain amplitude for optimal signal-to-noise ratio and the most precise test results, while avoiding any structural breakdown or slippage of the sample in the die cavity.

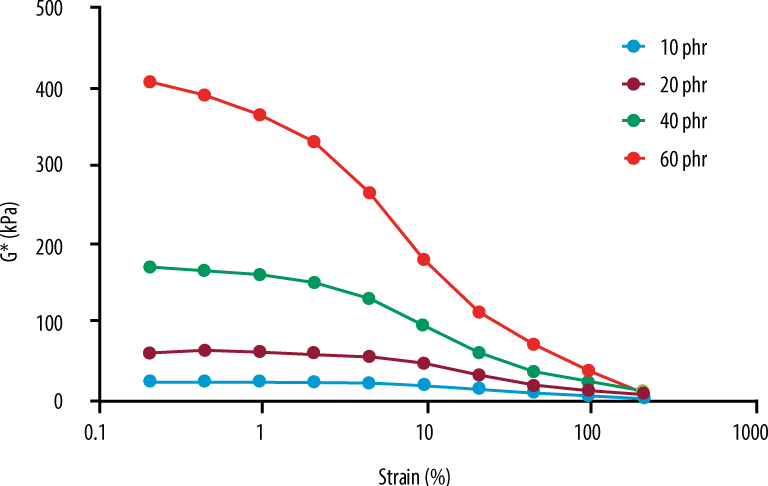

Rubber compounds are extremely sensitive to processing operations such as milling. Increasing strain causes the carbon black network - which is held together by Van der Waals-London attraction forces to break, causing a decrease in shear modulus of filled rubber vulcanizates. Therefore, MonTech Rheometers provide simulation capabilities for almost any possible production process, providing irreplaceable data for developing rubber compounds, as well as understanding and simulating manufacturing processes and environments.

The Payne effect is a particular feature of the stress-strain behavior of rubber, especially rubber compounds containing fillers such as carbon black and silica. Physically, the Payne effect can be attributed to deformation-induced changes in the material‘s microstructure, i.e. to breakage and recovery of weak physical bonds linking adjacent filler clusters.

Measurement of modulus vs. strain is therefore essential to understanding and quantifying filler loading, filler dispersion and filler-filler interaction in the low strain region, and polymer-filler interaction at higher strain. The resulting characterizations of material structure are essential as they directly impact dynamic stiffness and damping behavior of final products such as rubber bushings, automotive tyres and all other rubber goods. Similar to the Payne

effect under small deformations is the Mullins effect, which is observed under larger deformations in the non-linear viscoelastic range.

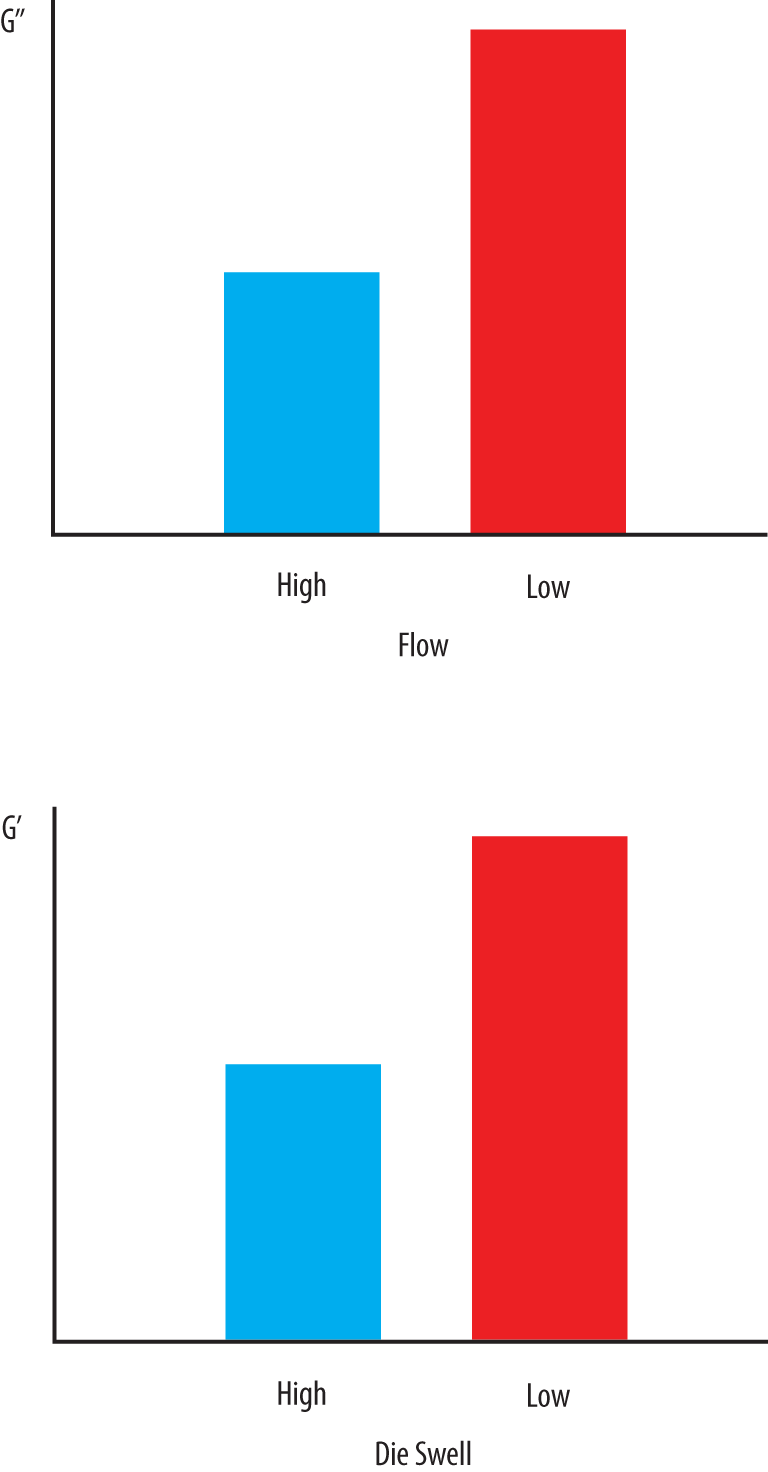

Good processing performance is influenced by three main criteria: throughput flow, die swell and surface finish.The rubber is required to flow through the extruder. The flow will be controlled by the viscosity of the rubber. The shear rate from an extruder and extrusion die can easily be calculated and used as the specific test parameters in a Rubber Process Analyzer test setup. The shear rate in MonTech Rubber Process Analyzer is proportional to the frequency multiplied by the oscillation angle.

A low viscosity will mean than rubber will easily flow through the extruder with low die pressure.Once the rubber is extruded it is required to be in the correct size – however as the rubber is extruded through the die it is in compression across the direction of flow and extension in the direction of flow. When leaving the die, the elastic nature of the compound will cause the rubber to expand, resulting in die swell. MonTech Rubber Process Analyzers can obtain the Storage shear Modulus G' at high strains (typically 100%) allowing an excellent prediction of die swell.

The surface finish of the extrudate is required to be smooth, and not rough. Roughness tends to occur when a stick-slip resonance is set up between the speed of the extruder and the elastic response of the compound. Testing at variable shear rates using a frequency sweep allows the comparison of compounds that extrude with smooth and rough finishes revealing processing differences in the storage shear modulus G'.

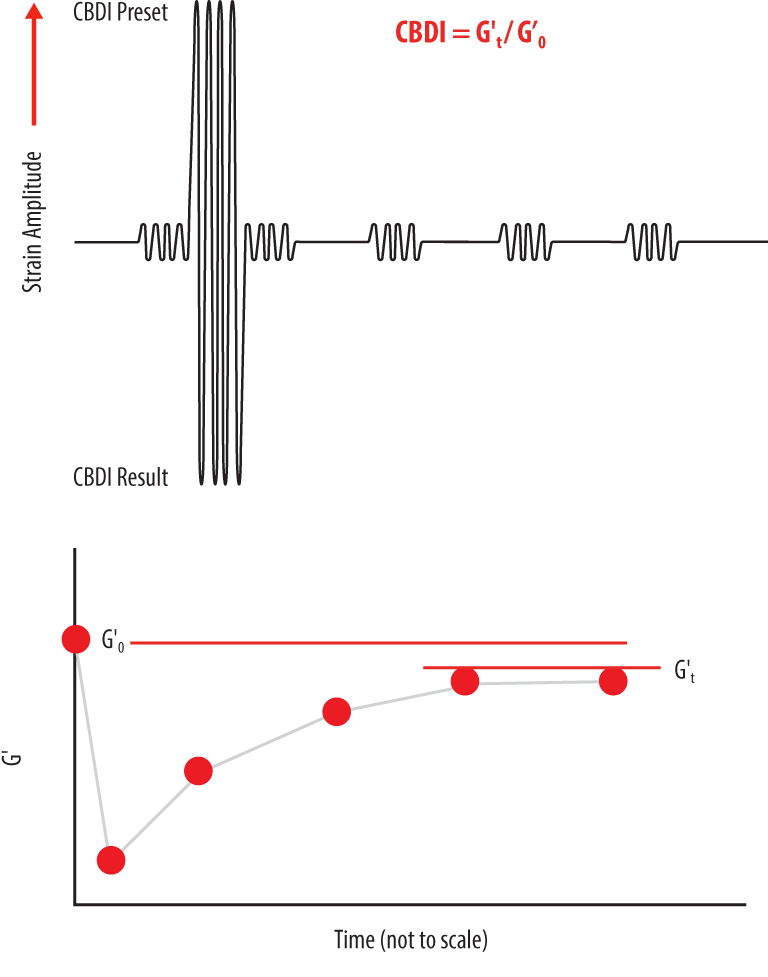

In filled rubber compounds carbon-black particles form a network of mutually interactive agglomerates. These effects can me measured and quantified using a simple D-RPA 3000 Matrix test. Storage shear modulus (G’) results at low strains (e.g. +/- 1%) are typically high and get reduced after a larger strain amplitude (e.g. +/-50%) is applied for a short period of time. With lower strain amplitudes applied over time, the reduced Storage shear modulus (G’) will partially recover. This effect relates to the Van der Waals forces linking the agglo-merates, getting broken at higher strain amplitudes and the partially recovering over time.

The extent of recovery of the Storage shear modulus (G’) directly relates to the Dispersion Rating (DR) of the rubber compound. If the carbon black is poorly dispersed, the recovery of the Storage shear modulus (G’) will be much lower indicating a much weaker filler structure and therefore reduced mechanical performance properties.

A simple CBDI performed by a Rubber Process Analyzer allows consistent testing and quality control on the Carbon Black Dispersion rating: CBDI = Inital storage shear modulus G’ (50°C, 1Hz, 1%) / Final storage shear modulus G’ (50°C, 1Hz, 1%). The higher the CBDI value, the better the carbon black dispersion.

Phone:

+49 (0) 6281 5622 30

Still not found what you're looking for?

MonTech rubber testing instruments are either available in standard versions or can be built according to individual customer requests and requirements. Contact us!