Oscillation strain

+/- 0.1°, 0.2°, 0.5° (Standard), 1°, 3° or 7.17°, Mechanically adjustable

(+/- 1.4%, 2.8%, 7% (Standard), 14%, 42% or 100%)

MDR 3000 Basic

Compact, entry model instrument for repetitive quality control testing as well as simple R&D applications.

-

Instrument description

MDR 3000 Basic

Static testing

The MDR 3000 Basic is the easiest to operate and most cost-effective way to determine viscoelastic properties of polymers and rubber compounds before, during and after cure. The acquired data gives exact information about processability, cure characteristics, cure speed and the behavior of the compound after-cure, as well as optional pressure measurement for sponge rubber compounds.

The MDR 3000 Basic comes as a complete and ready-to-test set consisting of the Rheometer itself, an external Personal Computer with the latest Windows Operating System, TFT screen, keyboard and mouse, as well as a printer.

Like every MonTech Rheometer, the MDR 3000 Basic also features an Ethernet Interface and can therefore be directly integrated in any customer’s factory network, guaranteeing the most stable data transfer and communication in any laboratory or factory environment, allowing data access at the instrument and from remote and office workstations, creating a digital process chain and integrated workflow based on a digital data repository, eliminating the need of result printing after each test series.

Designed as a table top instrument utilizing only minimal benchspace, the MonTech MDR 3000 Basic is synonymous with a reliable but easy and efficient testing operation. The instrument is equipped with the latest PLC-based control and data acquisition electronics, ensuring the highest data acquisition precision and reliability, along with superior temperature control – improving overall data significance and laboratory efficiency. The instrument comes with the MonControl Analysis software for test configuration management, data recording, automated Pass/Fail testing, processing of historical data as well as online statistical process control (SPC), having more than 3500 different datapoints available for selection. With an optional 5“ instrument touch-control panel, the instrument can even be conveniently operated in stand-alone mode by directly displaying and printing the most essential datapoints – including the possibility to save and archive test data on a USB flashdrive.

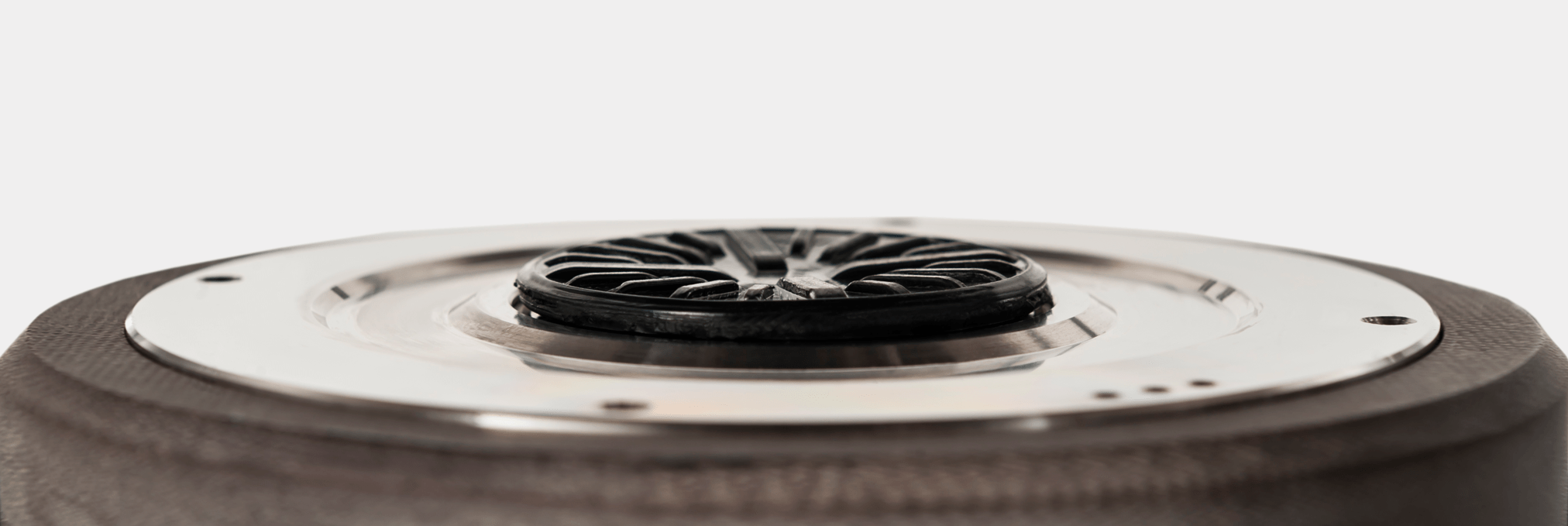

Completely closed, rotor-less, sealed, biconical test chamber system

Entirely made from stainless steel, precision machined, hardened and ground to utmost precision for highest durability and testing accuracy. The lower die is directly connected to the central shaft and drive system. All these parts and components are also made from solid stainless steel, making the MDR 3000 Basic a cost-efficient, long-lasting and safe investment. The upper die is attached to the reaction torque measurement for immediate recording of the material feedback at the highest precision.

The MDR 3000 Basic features an extremely stiff, ultra-rugged loadframe paired with a unique, column-guide-free, accessible testing area along with the most simple singlebutton operation and integrated multi-color status bar making this instrument truly the most reliable testing system for quality control purposes not only in the laboratory, but also directly in the production area. Of course various different automation options for increasing testing productivity are available and can be fitted to the instrument at any time.

Automation options

All MonTech Moving Die Rheometers as well as Rubber Process Analyzers can be easily automated, allowing customers to increase productivity and release operators for other important tasks.

MonTech offers the worlds largest Rheometer Automation portfolio designed for our customers to rely on – in the lab or on the shopfloor, in multiple shifts, 365 days, every year. Depending on the selected type of automation system, samples are loaded and unloaded automatically from linear or rotary trays, film is fed and tested samples are removed automatically.

Of course, every automated machine can – within a single click – also be switched into manual operation mode.

Instrument options

For specific testing requirements MonTech offers a variety of instrument options to customize a testing solution exactly for your specific requirements:

– Forced air and low-temperature cooling systems

– Axial force transducers

– Cavity pressure control systems

– High speed data acquisition systems

– Data, IT and software integration

– Advanced productivity options -

Applications

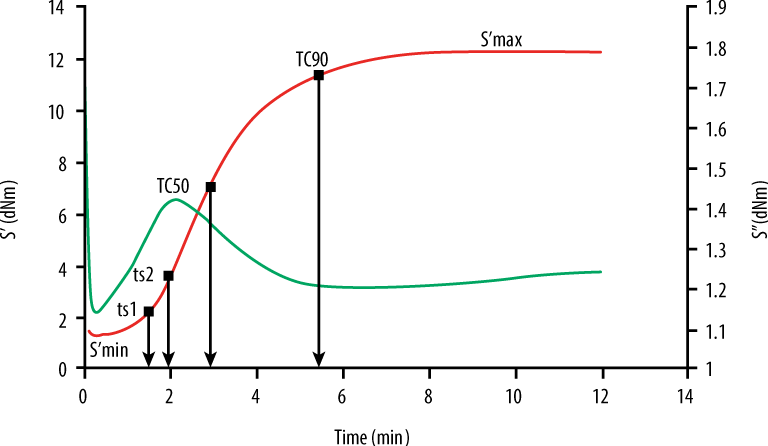

Isothermal Cure

Isothermal cure experiments are the most common type of test for quality control in rubber and elastomer processing. MonTech Moving Die Rheometers provide high precision data as well as a simple operation of the instruments. All the important characteristics, such as minimum / maximum elastic torque, scorch times, cure times and reaction rates are precisely calculated, with over 3500 different datapoints. All data is available in numerical as well as graphical form; limits, control gates and tolerance graphs can easily be set, and Pass / Fail status is automatically evaluated after each test.

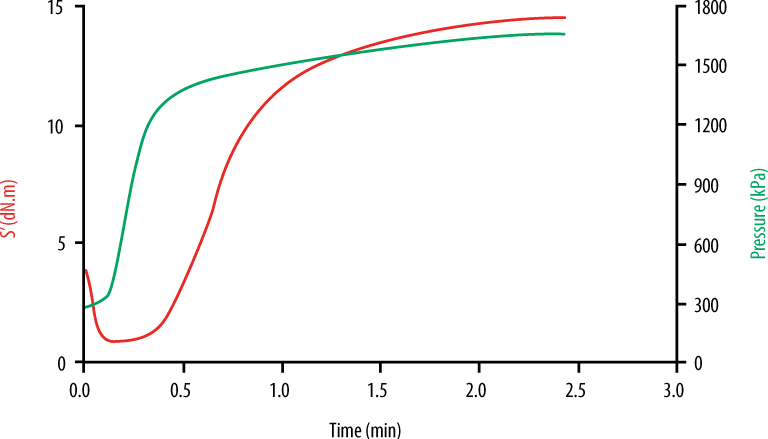

Cure with simultaneous Sponging / Foaming / Blowing Reaction

Especially for sealing applications, blowing agents form a vital part of compound recipes in order to produce a cellular structure via a foaming process that runs in parallel to the cure reaction. The cellular matrix structure which is created during the foaming process reduces density, increases thermal and acoustic insulation, and affects the relative stiffness of the mix. Therefore, MonTech Rheometers can be fitted with a precision normal force measurement transducer in the die cavity in order to calculate cavity pressure simultaneously during the curing and reaction in a single test, and revealing interrelations between the two reactions.

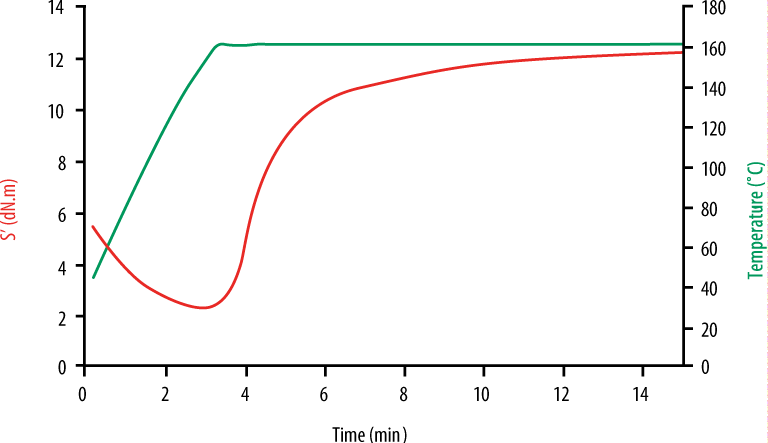

Non-isothermal Cure

In addition to isothermal static cure testing, MonTech MDRs and RPAs can perform tests at variable temperatures. These non-isothermal sequences can be programmed in order to follow virtually any temperature profile, making them especially valuable for the simulation of manufacturing processes which are usually not isothermal. Typical processes that can be simulated are mixing, milling, extrusion, compression moulding, injection moulding, and storage conditions. Of course, non-isothermal test sequences can be executed in a single test with any other static or dynamic sequence, such as strain and frequency sweeps, providing the most accurate data of the material‘s behavior at any production stage and material state.

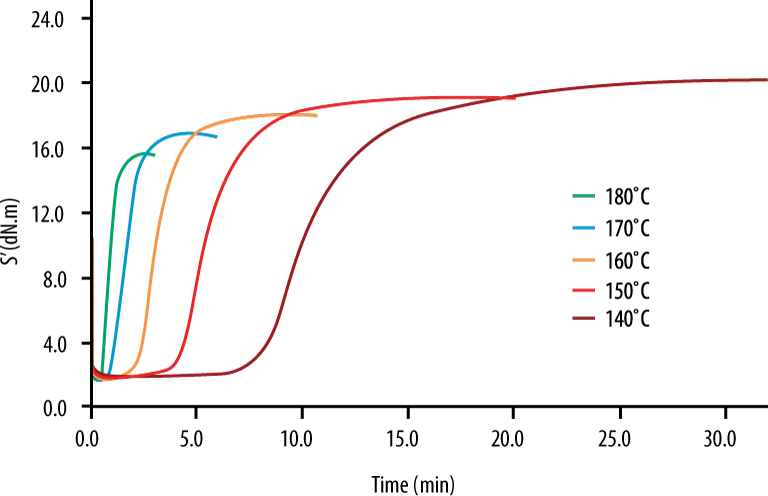

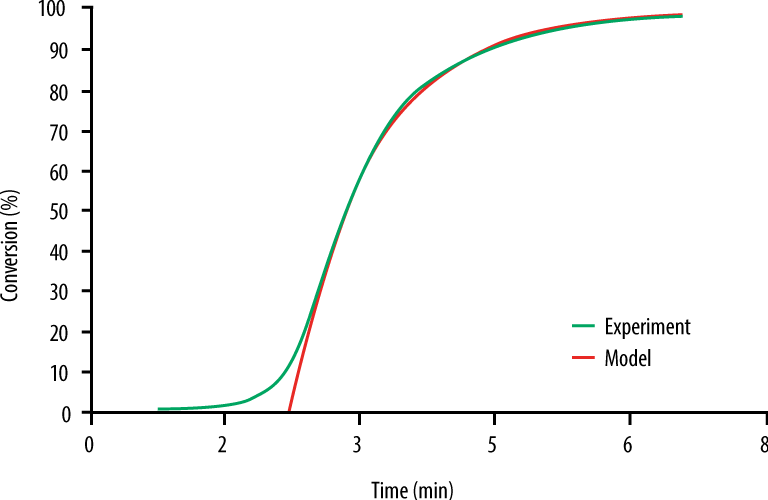

Advanced cure kinetics modeling

Test data from similar static or dynamic test sequences executed at different temperatures can automatically be evaluated and modelled for an advanced cure kinetics analysis, providing information about Reaction Rate, Order of Reaction (n), Rate Constant (k), Activation Energy (E) and Incubation Time (ti).

Advanced cure kinetics modeling

-

Technical Specification

Technical Specification

-

International standards

ISO 6502, ASTM D 5289, DIN 53529

-

Die configuration

Biconical, closed System, sealed

-

Drive system

Mechanical, brushless DC eccentric drive

-

Oscillation frequency

1.667 Hz (100 cpm)

-

Oscillation strain

+/- 0.1°, 0.2°, 0.5° (Standard), 1°, 3°, 7,17 (100%), Mechanically adjustable (+/- 1.4%, 2.8%, 7% (Standard), 14%, 42%, 100%)

-

Torque range

Ambient to 232 °C

-

Measured Data

Torque (dNm, lbf.in, kgf.cm), Temperature (°C, °F), Pressure (bar, kg per cm²), Time (min - min / min - sec / sec), Shear rate (1/s, rad/s), Cure rate (1/min, 1/sec)

-

Calculated Data

S΄, S˝, S*, tan δ, phase angle, cure speed, ...

-

Die gap

0.45 mm nominal

-

Sample volume

approx. 4.5 cm³

-

Machine frame

Rugged 4 column frame with 4 stable posts - Large post distance for easiest access to test dies for sample loading, cleaning and maintenance - Pre-tensioned tiebars for highest rigidity avoiding any frame deformation under load - Integral crosshead with guiding on all 4 posts for precision parallel closing of test dies - Intelligent die alignment by special coupling of main cylinder to moving crosshead ensuring perfect and uniform pressurized sealing of test test - Symmetrical alignment due to auto-alignment feature, mechanical and thermal symmetrical frame compensating for non-compliance ensuring highest precision of test results

-

Closing system

Pneumatic with soft-close to prevent foil rips

-

Temperature control system

Ambient to 232 °C, precision +/- 0.03 °C, Max. heating rate: 85°C/min digital, microprocessor PID controlled

-

Temperature check system

Recordings of the temperature gradient on the screen, microprocessor monitored

-

Data Interface

Ethernet (10/100 MBit), USB (int.), CF card (int.), RS232 (opt.)

-

Data points

Over 3500 data points available for each test Including S‘ Min, S‘ Max, TS 1, TS 2, TC 10, TC 30, TC 50, TC 90

-

Pneumatics

min. 4.5 Bar / 60 psi

-

Electrical

Single phase 100 - 120 V, 8 Amps or 200 V - 240 V, 5 Amps

-

Instrument options

- Instrument control panel with 5“ touchscreen display and printer - Selectable oscillation frequency 1,67 / 0,83 Hz (100 / 50 cpm) - Adapted transducers for high or low-viscosity torque range - Normal force / Pressure measurement - Single channel forced air cooling system - Extended thermal range to +300°C - Autoloader 5 or 10 sample linear - Autoloader with 24 or 48 sample tray - R-VS 3000 constant volume sample cutter - Label Printer - Signal tower - Dustproof version / Safety package

Calculated results

Parameter

-

-

Options

R-VS 3000

The R-VS 3000 Rheometer sample cutter is designed for the fast, safe and easy preparation of Rheometer test samples with a constant sample volume, significantly reducing operational variability and increasing test result reproducibility.

R-VS 3000MCool -40°C

The MonTech MCool -40°C is an advanced external liquid cooling system for use in the D-RPA 3000 and MDR 3000 Professional. It is perfect for testing where extreme low temperatures

MonTech News MCool -40°C

are required, approaching glass transition temperature. The system works in conjunction with the pneumatic cooling system and cools both dies individually, reaching temperatures as low as -40°C (-40°F). This patented cooling system serves as an addition to the instrument’s temperature control, leaving the existing heating system in the dies unchanged and fully operational. All instruments equipped with the MCool -40°C cooling system maintain full functionality of a Moving Die Rheometer or Rubber Process Analyzer

Automation options with 24 samples

Completely closed, rotor-less, sealed, biconical test chamber system

Specific Standard and Application Search

With our intelligent application and standard search you can find products for applications and DIN, ISO, ASTM, BS, AFNOR, JIS and TGL standards in a few seconds.